Wet Coating

Uniform paint coverage, precision application, and corrosion protection

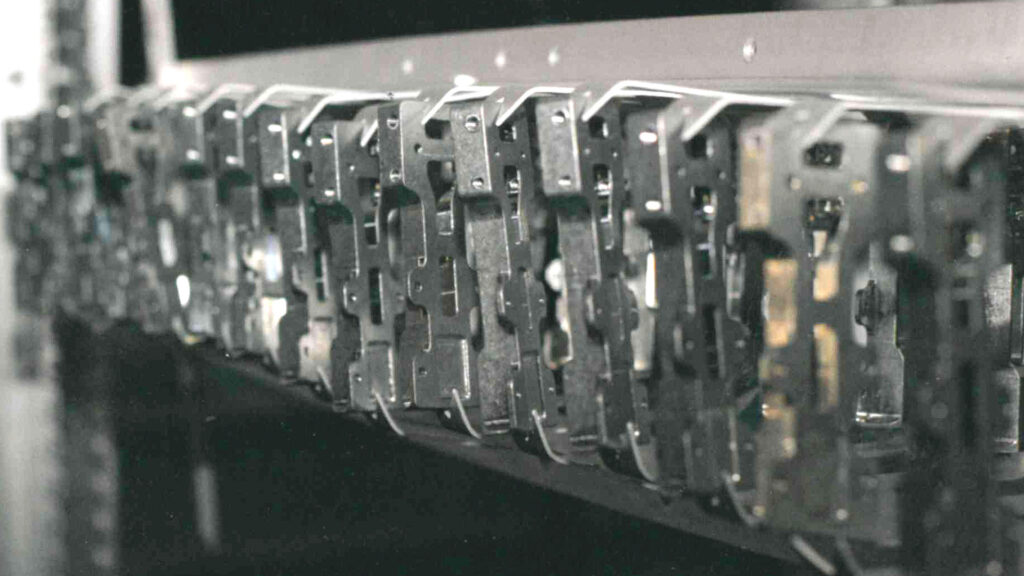

AZZ’s high-quality wet coating operations have established us as a leading provider of protective finishes, including chemical agent resistant coatings (CARC) for military equipment. Our expansive capacity enables us to finish parts up to 40 feet in length, and include high-spec, intricate parts, and masking.

Wet coating is an effective method of applying a protective coating of liquid paint evenly to a wide range of materials, including:

- Plastic

- Fiberglass

- Wood

- Hydraulic Pumps

- Fiberglass

- Cold Rolled Steel

- Hot Rolled Pickled and Oiled (HRPO) Steel

- Stainless Steel

Custom Masking

AZZ has the technical capabilities to provide custom masking to protect matting and contact surfaces to our client’s manufactured components where critical tolerances must be maintained.

Related Featured Story

AZZ Surface Technologies Provides the Unmatched Precision of Wet Coating

AZZ’s ISO 9001 certified processes and unwavering focus on zero defects enable us to meet the most stringent quality standards.

Duplex Coating

Optimal protection achieved through the synergies created by combining hot-dip galvanizing and powder or wet coating

Powder Coating

Durable coatings which provide long-lasting corrosion protection in an array of colors and textures

Surface Prep

Highly skilled experts provide sandblasting services, the surface preparation critical for a consistent, high-quality finish