Sustainability is a built-in part of our process

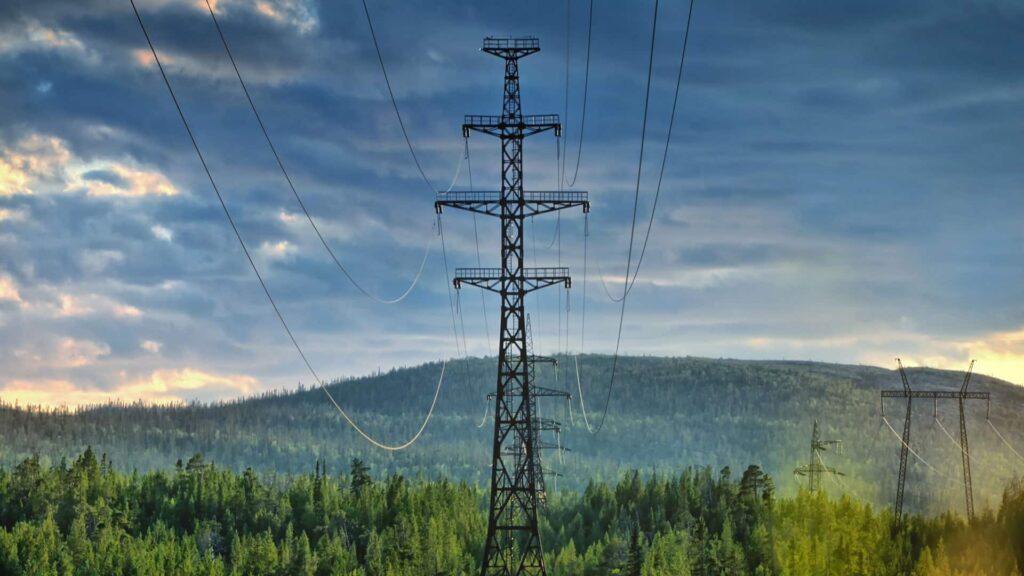

Protecting steel is at the very heart of our metal coating services. Ensuring that the key element of global infrastructure lasts as long as possible is the definition of sustainability. Eliminating the need to replace fabricated steel products, galvanizing saves energy and natural resources that would be required to create and transport new steel.

By using 100% naturally occurring zinc in our hot-dip galvanizing, we are part of a wholly recyclable process that provides maintenance-free corrosion protection that lasts for decades.

- Hot-dip galvanizing contains no Volatile Organic Compounds (VOCs)

- Steel is the most recycled product in the world

- Zinc and steel are 100% recyclable

- 30 percent of all zinc used comes from recycled materials

- Using hot-dip galvanized steel contributes points toward LEED® Certification

Related Featured Story

Sustainable Qualities of Hot-Dip Galvanizing

Exploring the Durable and Eco-Friendly Benefits of Hot-Dip Galvanizing for Long-Lasting Infrastructure.

Related Case Study

Greenhouse Water and Irrigation System

The greenhouse was a perfect candidate for the use of hot-dip galvanized (HDG) steel. Since the plants grown in the greenhouse require routine watering, the tenacious, water-resistant coating that forms from the zinc patina protects the steel from the corrosive, wet environment.

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

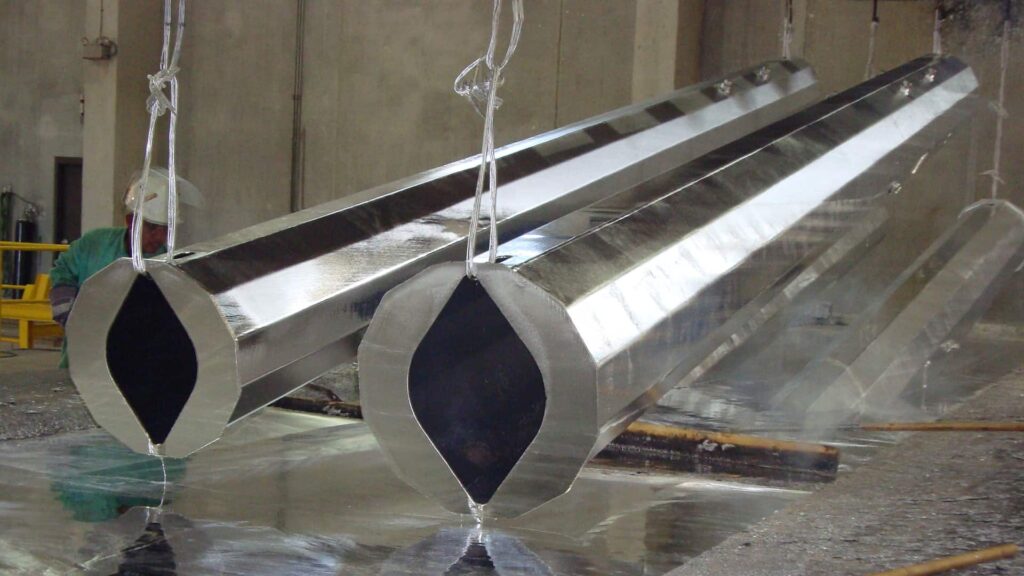

Hot-Dip Galvanizing Process

A tested and proven galvanizing process ideal for modern applications

Spin Galvanizing

Cost-effective corrosion protection for small to mid-sized steel components