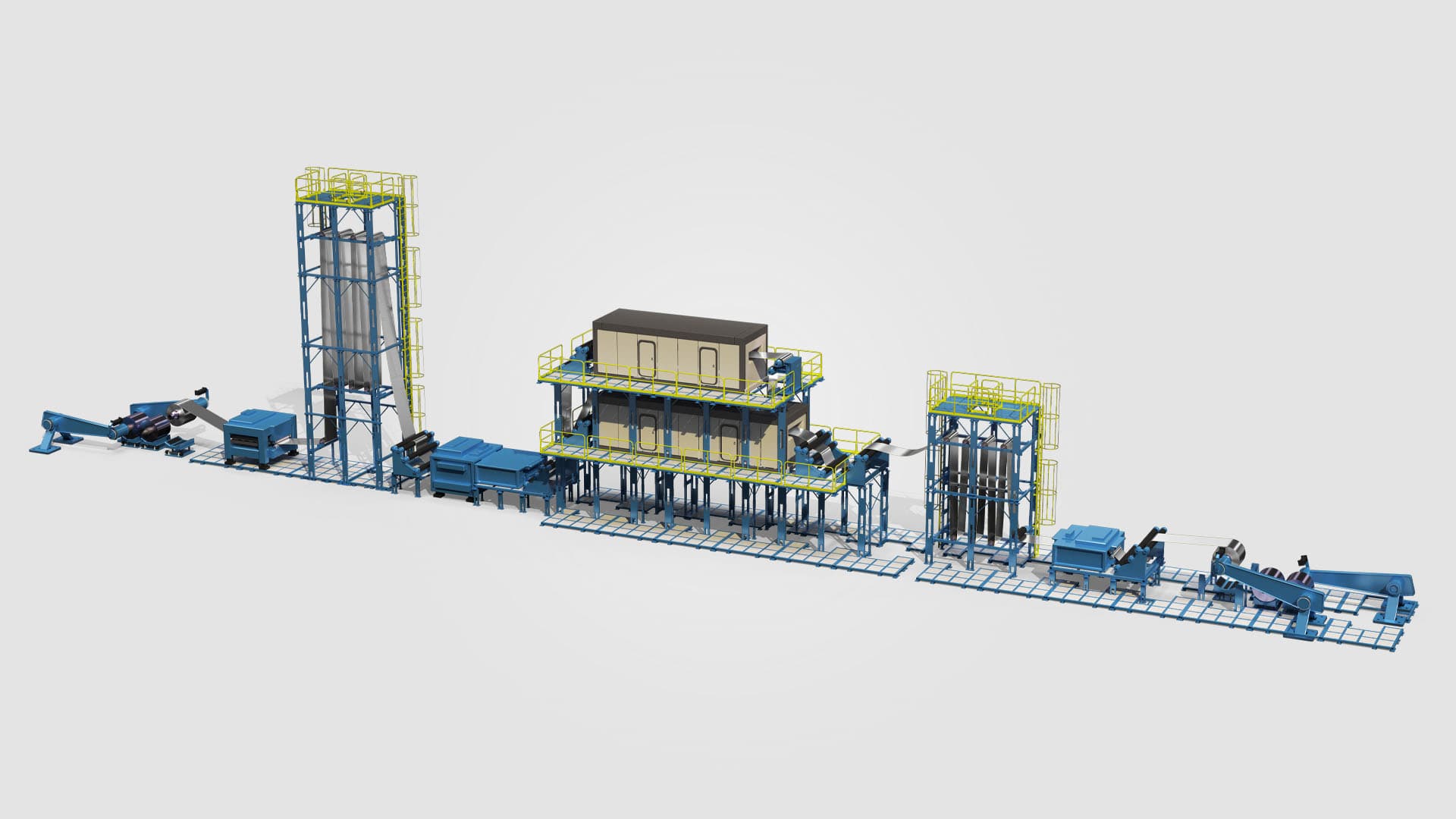

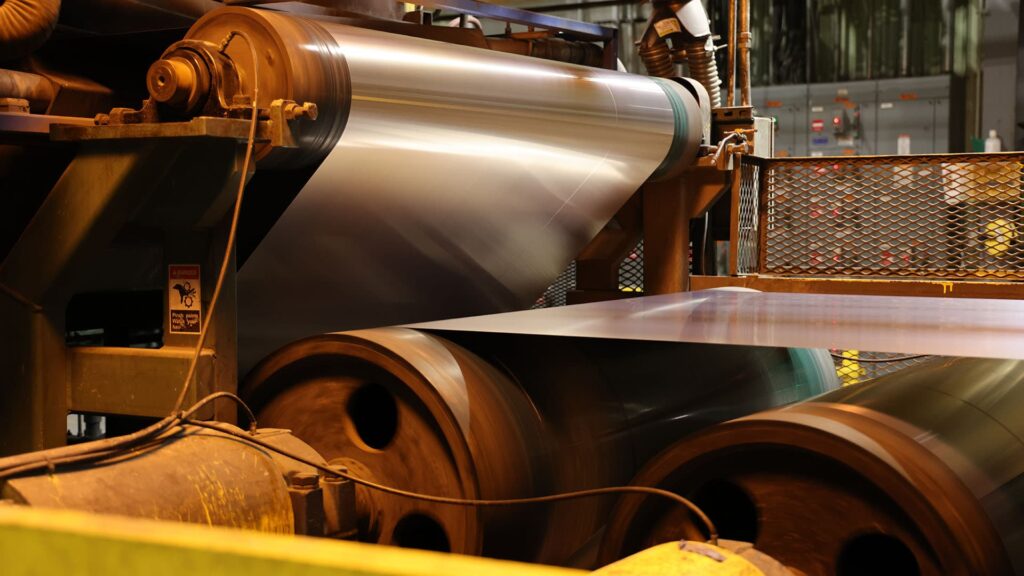

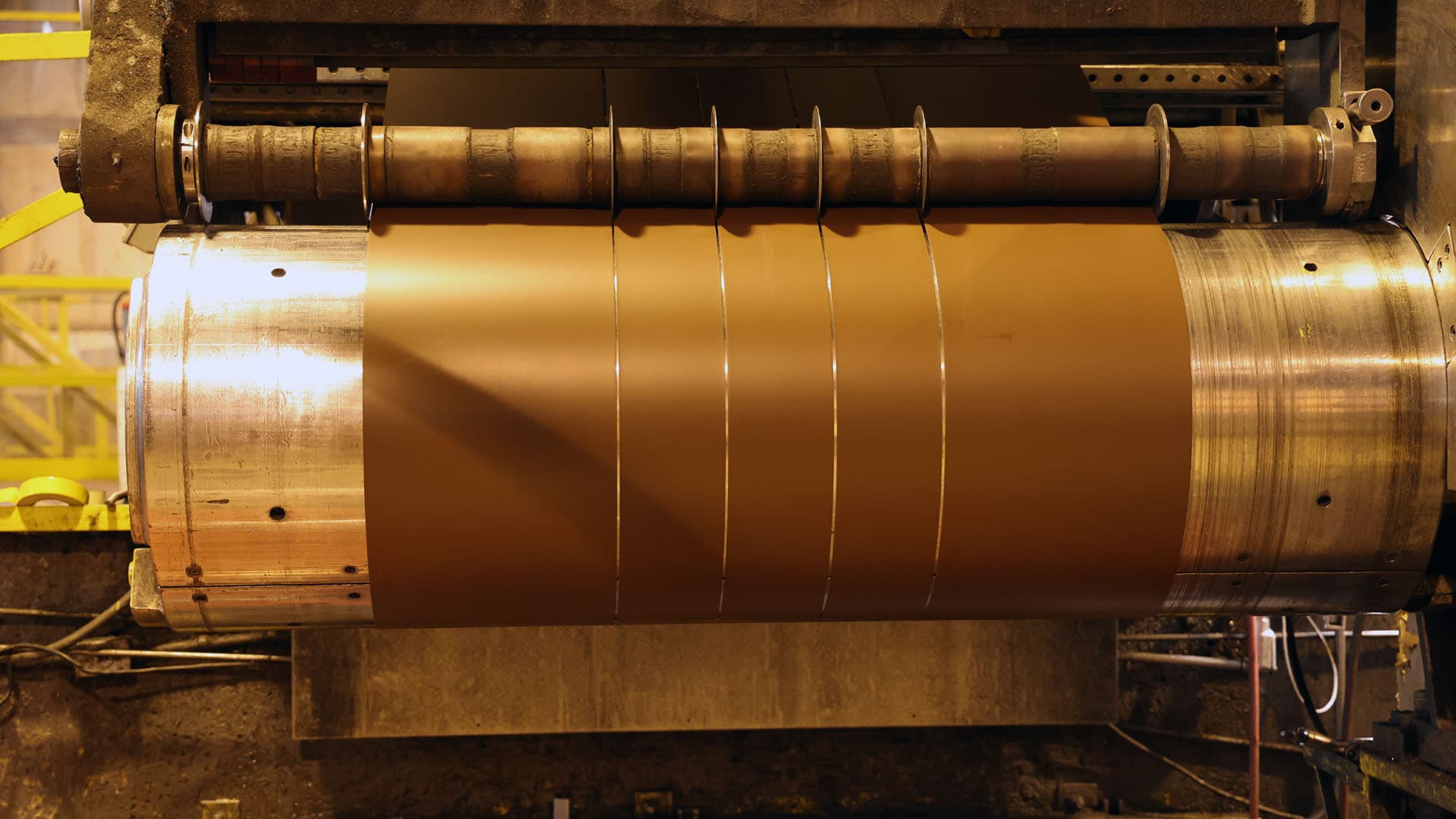

Slitting

Enhance efficiency, minimize waste, and maximize material

A critical capability in the coil coating industry, slitting is cutting wide metal coils into narrower strips or coils of specific widths. Slitting allows for efficient handling and distribution of the coated metal, accommodating various industry needs. Customizing the width according to customer requirements or application minimizes waste and optimizes material usage, saving time and resources in the production process.

Contact Us

Follow Precoat MEtals

CoilZone Login

Visit CoilZone

Your secure, interactive, supply chain management system.

Locations

Capabilities by Precoat Metals location

| Cut-to-Length | Embossing | Laminating | Printing | Shape Correction | Slitting | |

|---|---|---|---|---|---|---|

| Baltimore | • | Directional Stucco | • | • | ||

| Birmingham | Non-Directional Stucco; Seville | • | • | |||

| Columbia | • | Directional Stucco; Seville; Rough Sewn Cedar | • | • | ||

| Greenfield | Directional & Non-Directional Stucco; Seville 101; Rough Sewn Cedar | • | • | |||

| Hawesville | Seville 101 | • | • | |||

| Houston | ||||||

| Jackson | • | Directional Stucco | • | • | • | |

| Kingsbury | • | • | • | |||

| MMC | • | • | ||||

| Northgate | • | |||||

| Portage | • | • | ||||

| St. Louis | • | • | • | |||

| Weirton | • | • |

Learn About our Advantages

Coil Coating Process

Explore the continuous, automation of our coil coating process ensuring uniform, high-quality metal coated finishes before fabrication

Why Choose Coil Coating

Streamline processes, reduce costs, enhance product quality, and explore innovative coatings

Cleaning & Pretreating

Ensures the quality, durability, and performance of coated products

Shape Correction

Improves stability and appearance, meeting precise dimensional tolerances