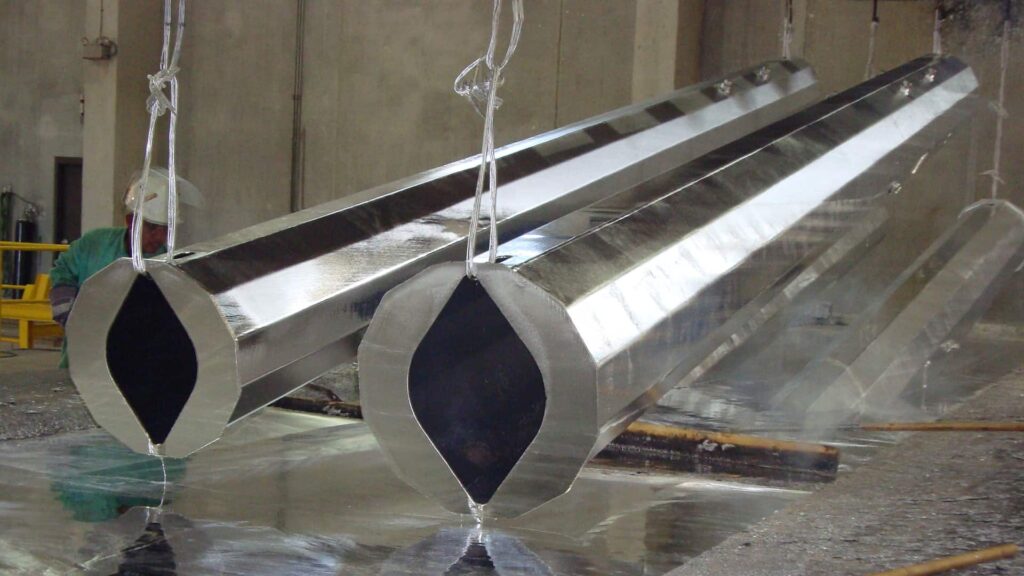

Hot-Dip Galvanizing Process

A tested and proven galvanizing process ideal for modern applications

AZZ’s GalvXtra galvanizing process uses a proprietary formulation of molten metals that produces the most consistent coating thickness available while also creating an even, enduring finish. Part of a four-step, hot-dip galvanizing process, GalvXtra meets ASTM A123, ASTM A153, and ASTM B6 requirements to deliver high-quality zinc coatings on ferrous materials.

Preparation

Steel arriving at AZZ’s galvanizing plant undergoes a thorough inspection to ensure drainage and venting requirements are met. Once in the staging area, careful handling ensures the material is transported efficiently and effectively through the initial cleaning process.

Cleaning

A critical part of the process is cleaning, which begins with a complete immersion in a hot alkali solution, to remove organic compounds and dirt. Next acid pickling removes rust or scale and finally fluxing eliminates surface oxides to promote intermetallic development.

Hot-dip galvanizing

The steel is submerged in a bath of molten zinc until it reaches 840° F (449° C). At this point, the zinc reacts with the steel to form zinc/iron intermetallic layers on all surfaces inside and out.

Post-dip quality inspection

The galvanized steel is cleaned, weighed, and carefully inspected. Calibrated instrumentation ensures quality standards are met and coating thickness, appearance, and compliance with ASTM specifications are all reviewed before final approval. Once completed, the galvanized product is ready to be shipped. AZZ can assist you with your transportation requirements.

Contact Us

Downloads

Locations

Related Featured Story

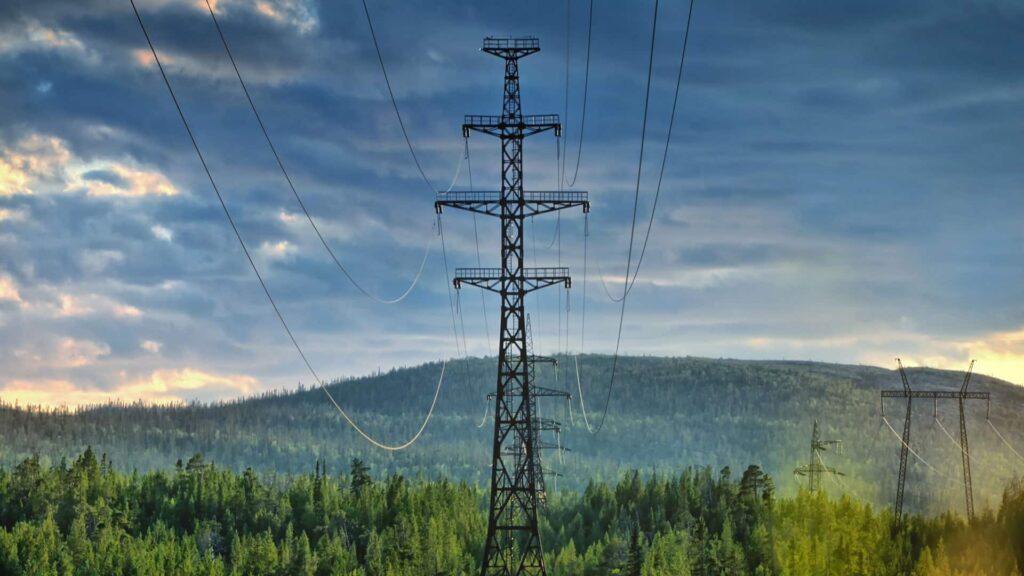

Protecting Metal Gratings: The Benefits of Hot Dip Galvanizing

Whether used in industrial settings, commercial buildings, or public infrastructure projects, metal gratings need to withstand a lot of wear and tear over time. Without proper protection, metal gratings can become corroded, weakened, and unsafe. That's where hot dip galvanizing comes in.

Related Case Study

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

Spin Galvanizing

Cost-effective corrosion protection for small to mid-sized steel components