About Spin Galvanizing

The durability of the smallest components can be critical to a structure’s integrity and performance. These small components often have intricate designs requiring that a protective coating does not interfere with surface integrity.

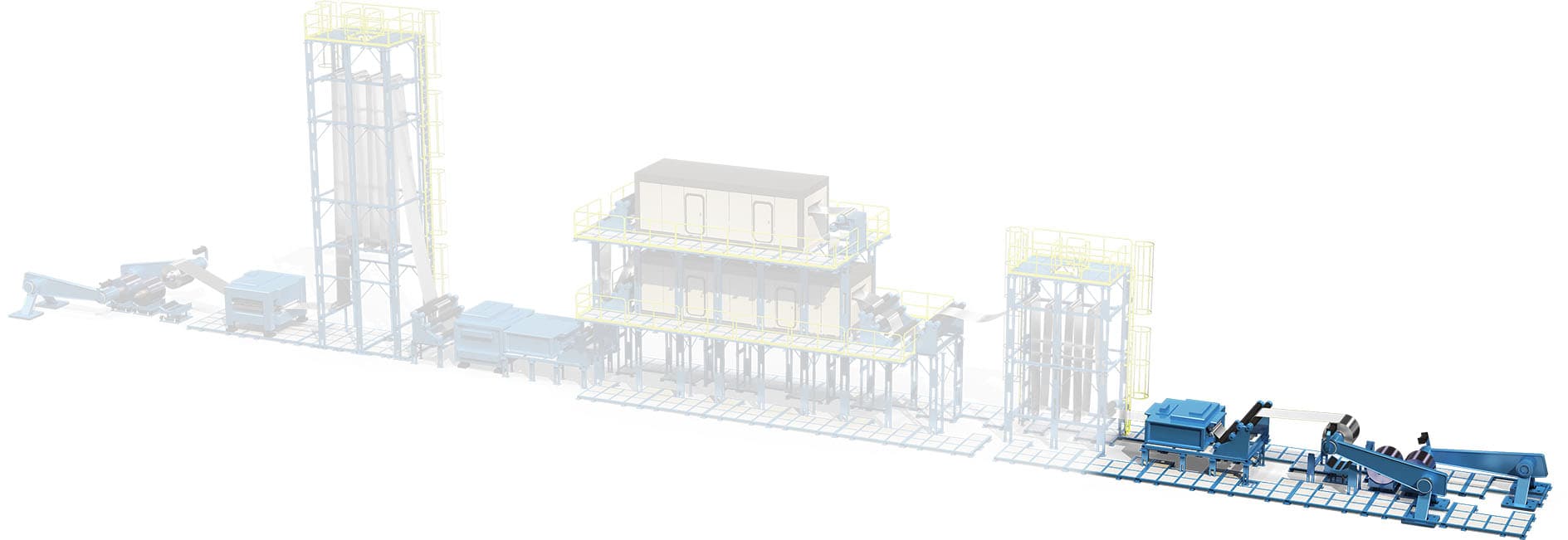

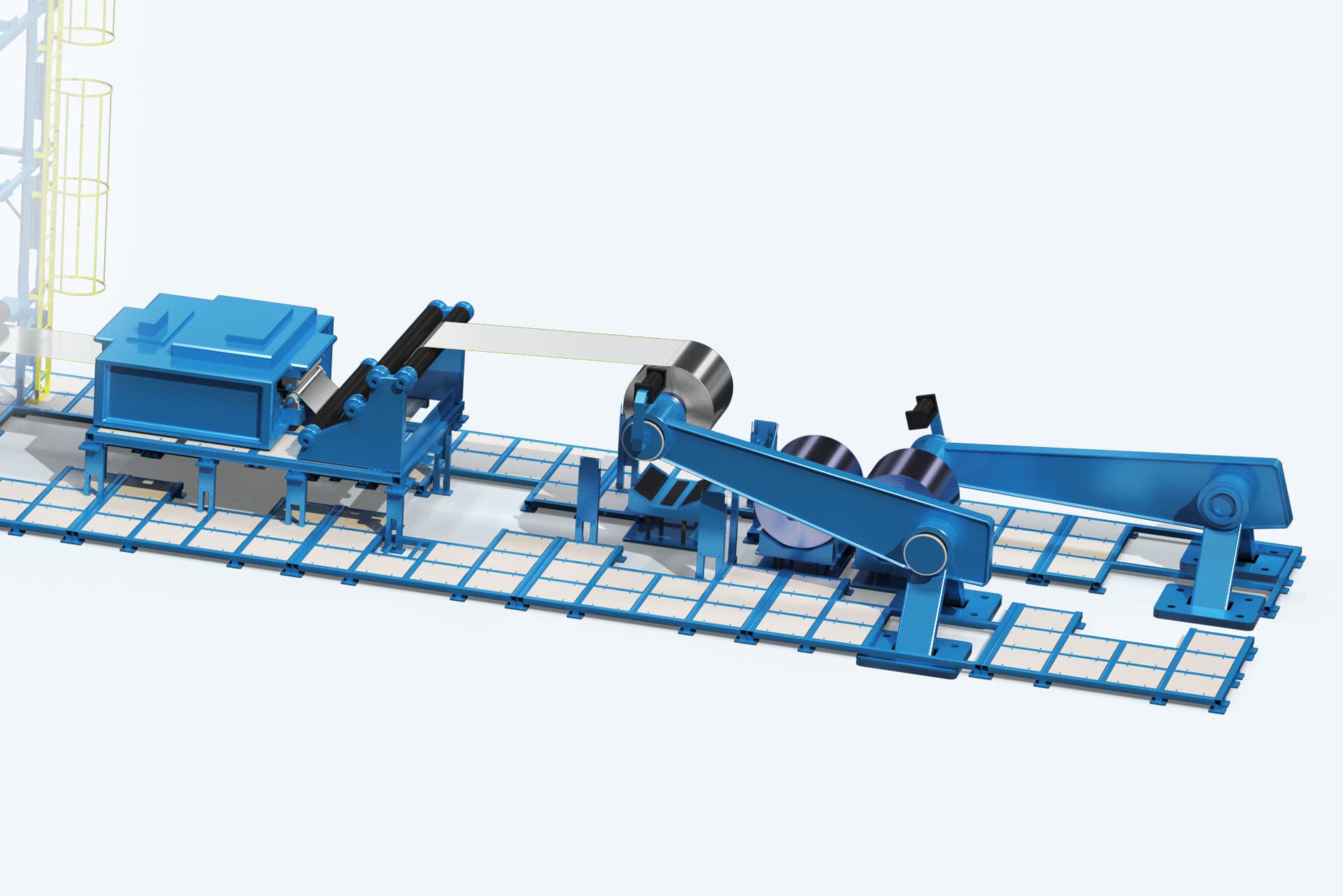

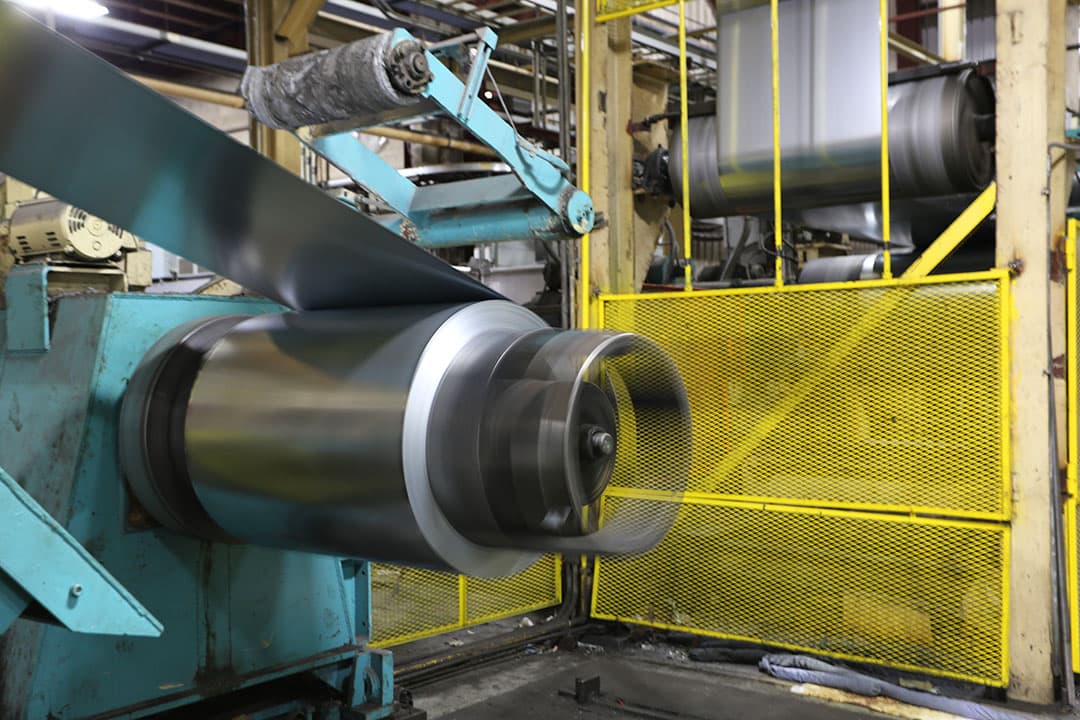

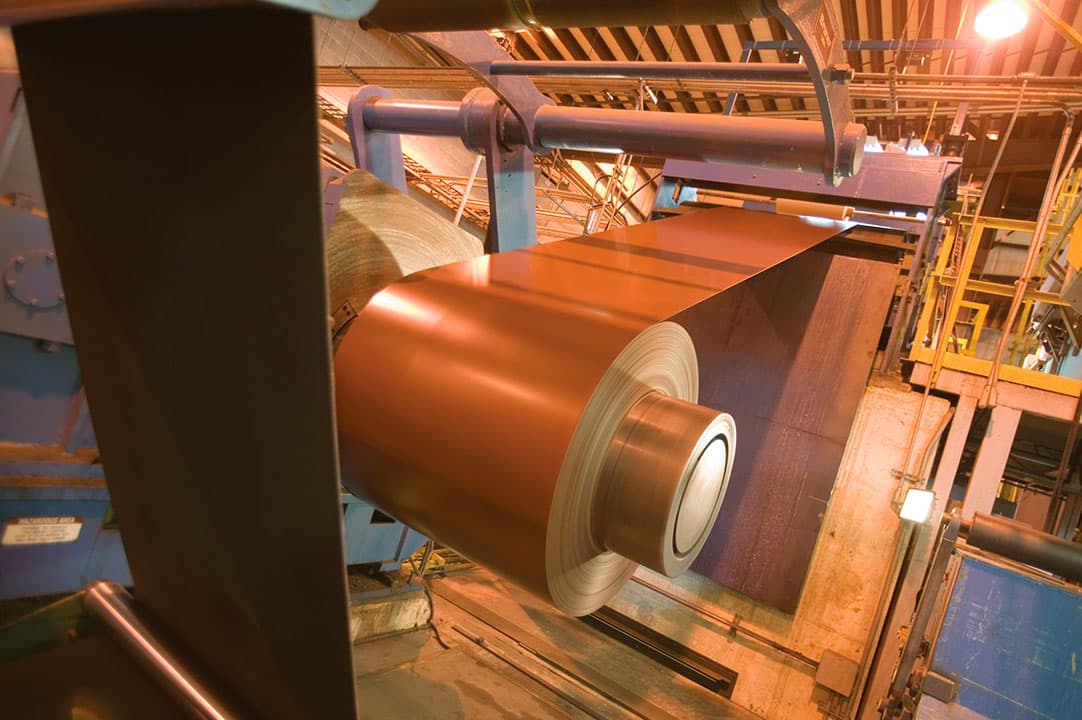

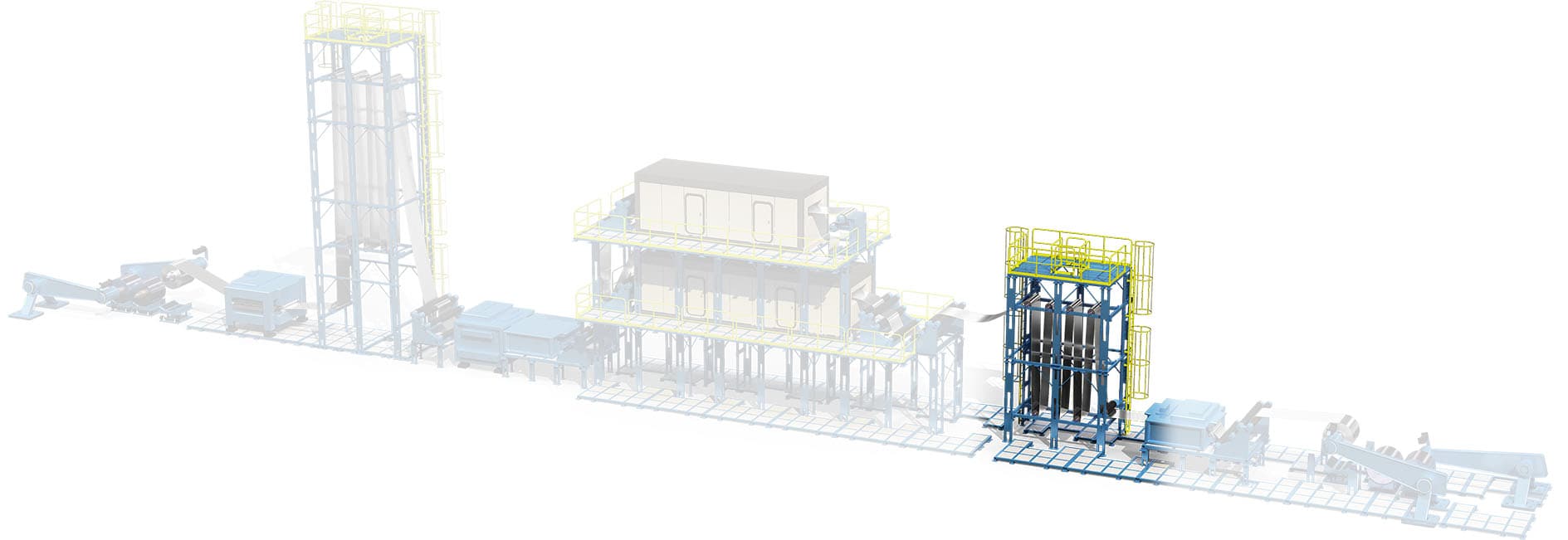

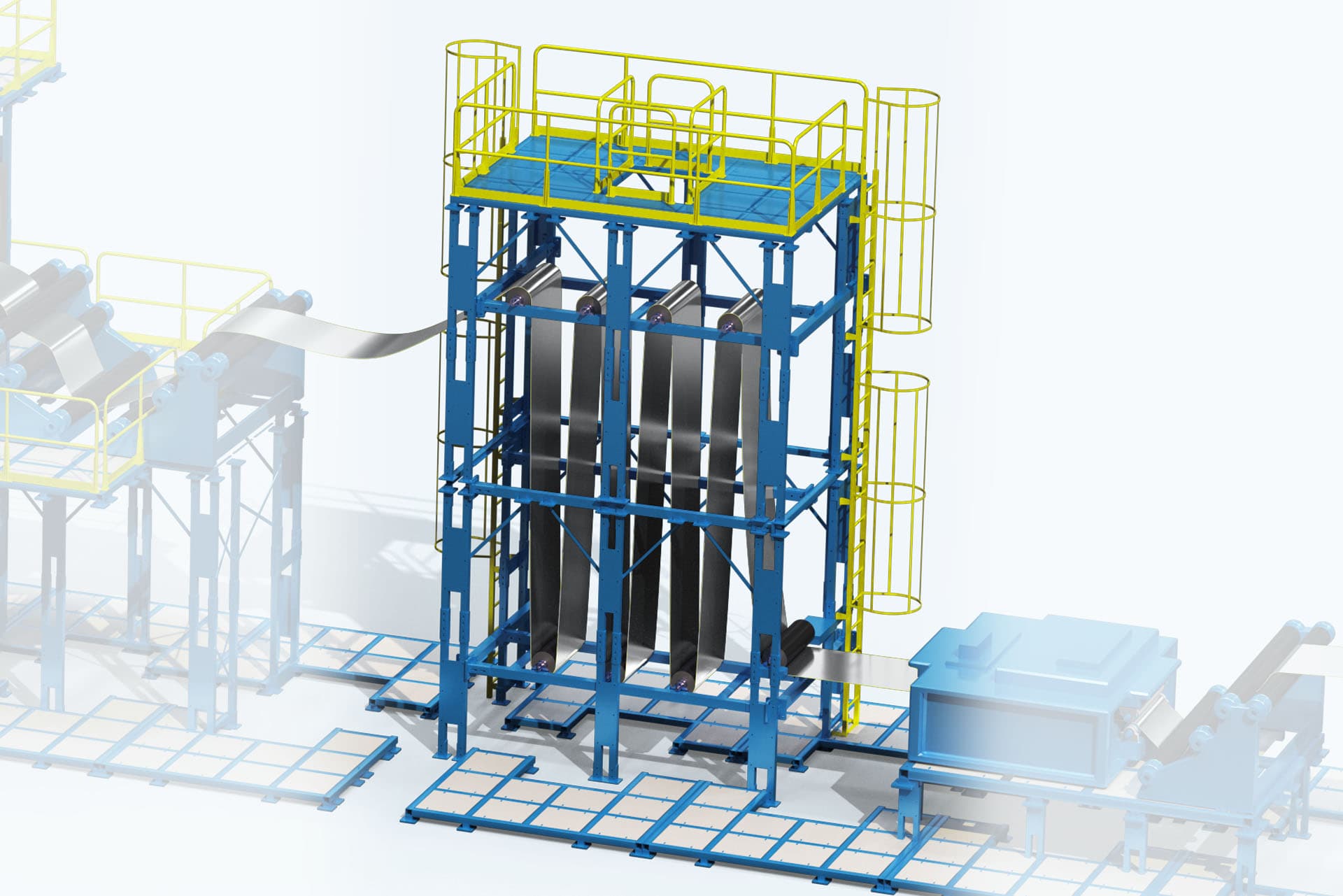

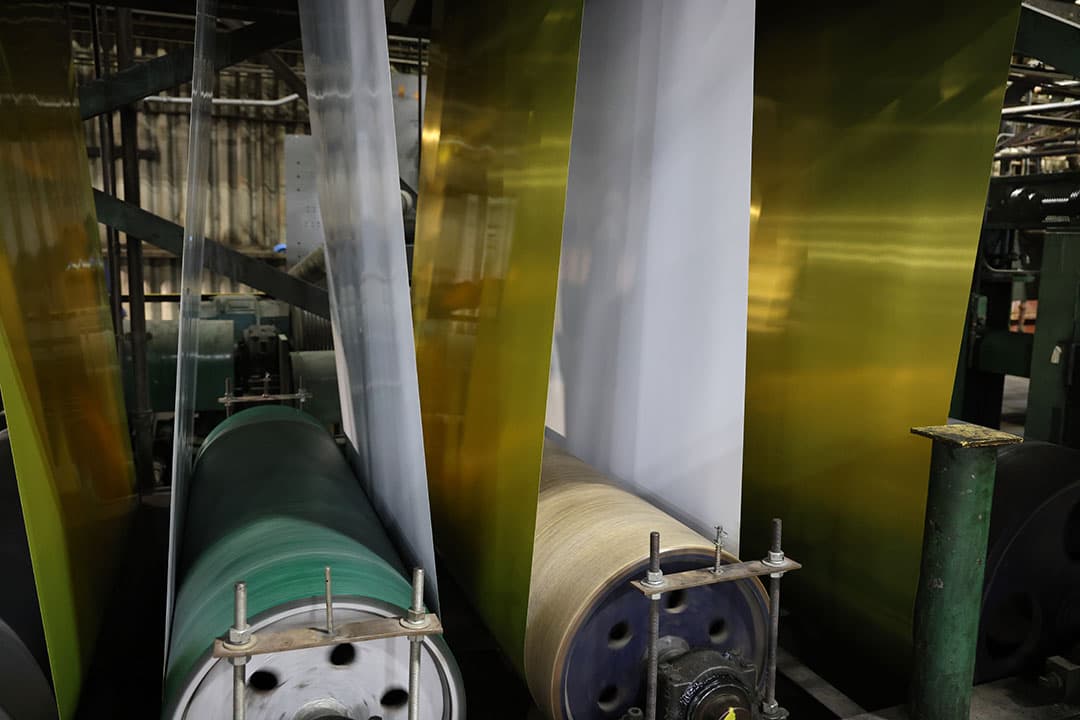

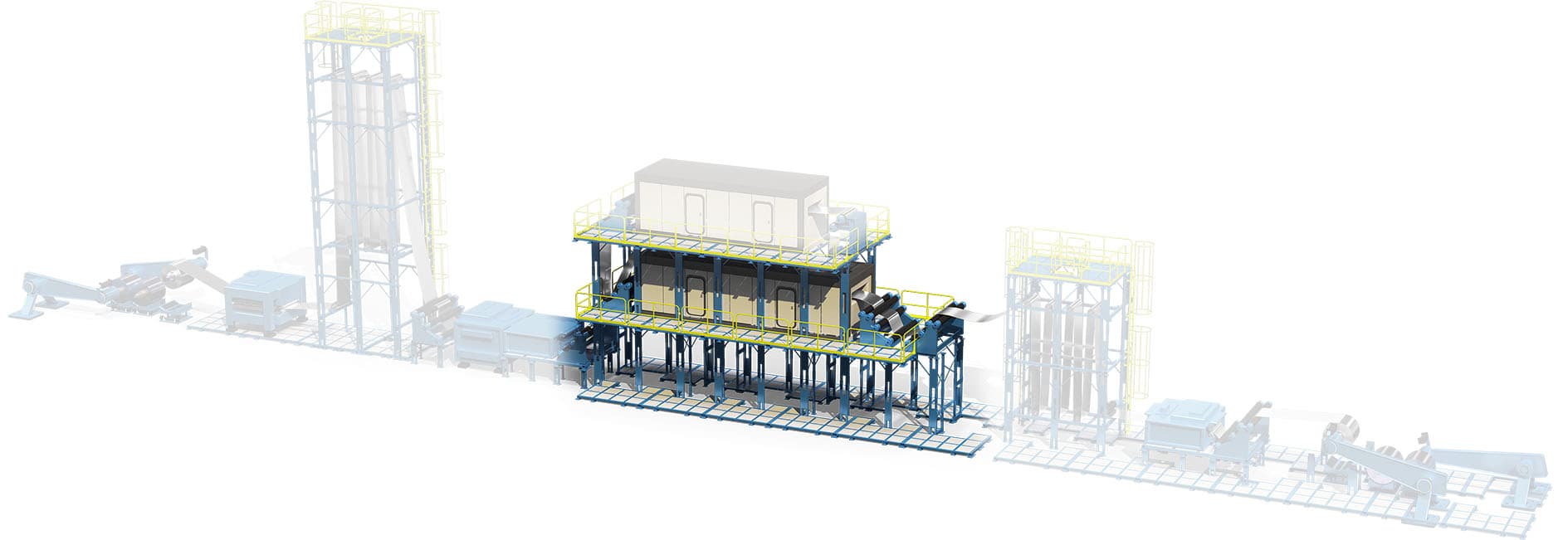

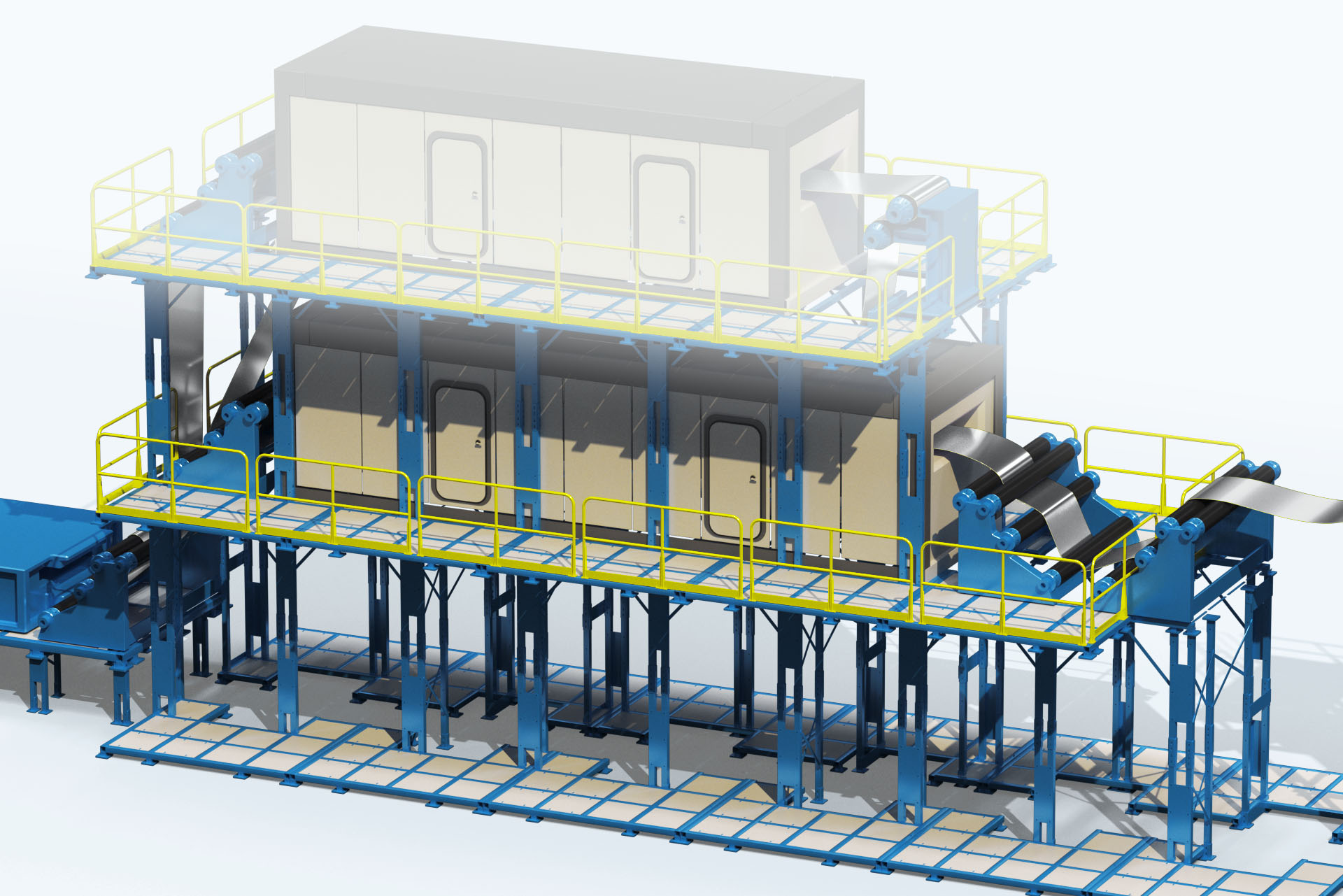

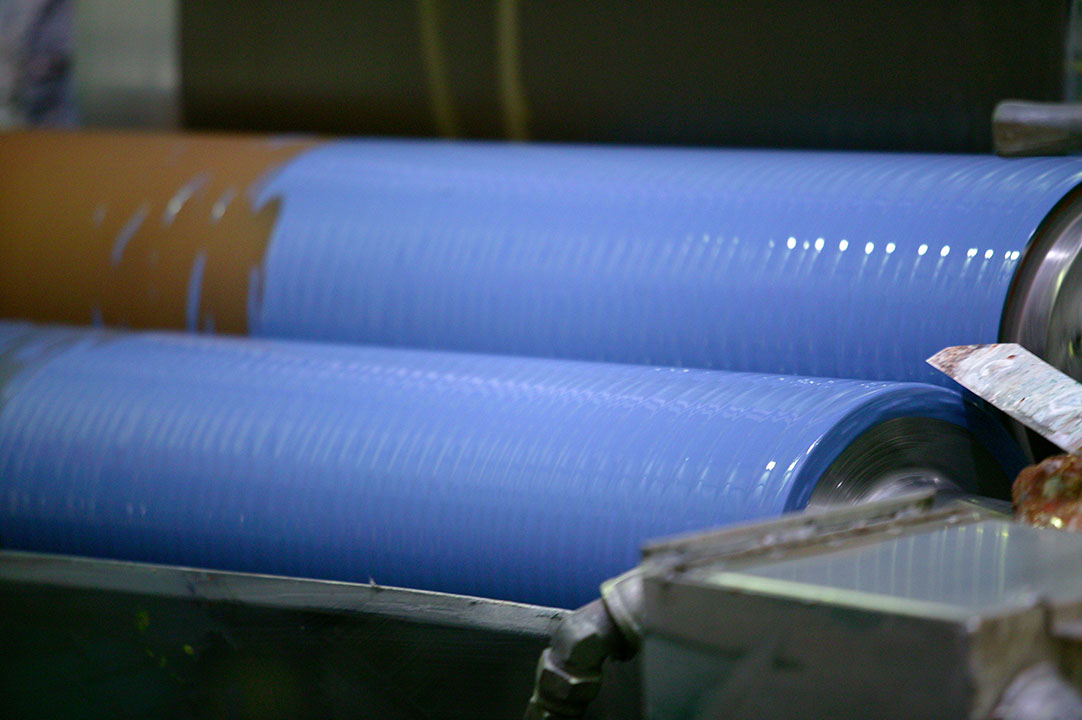

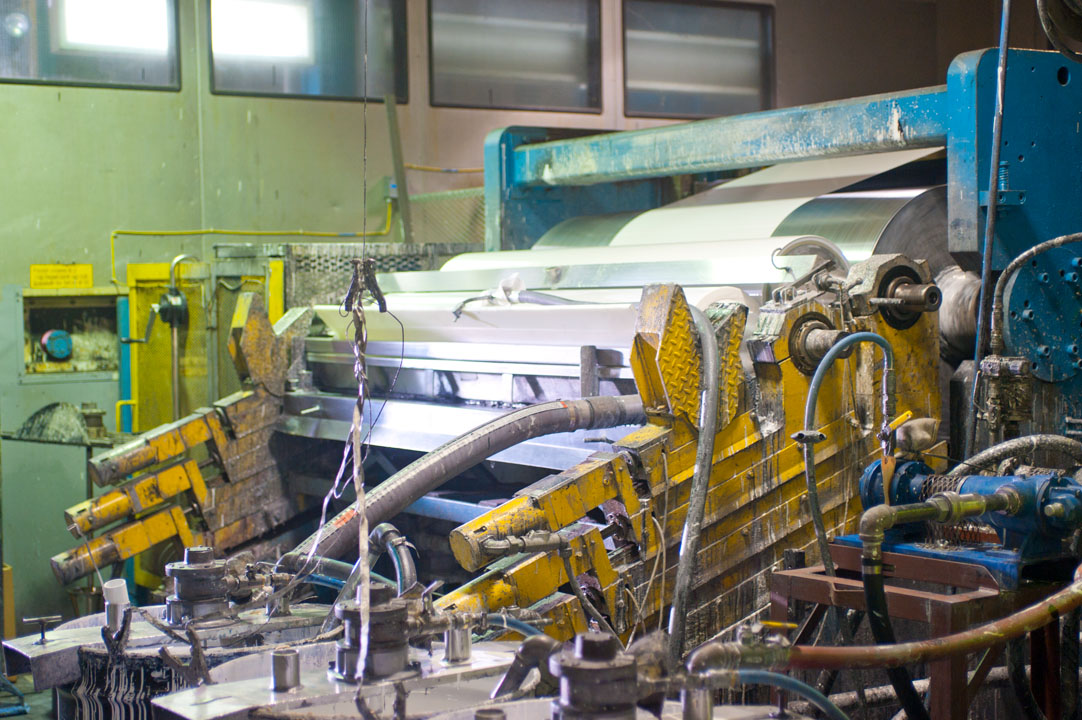

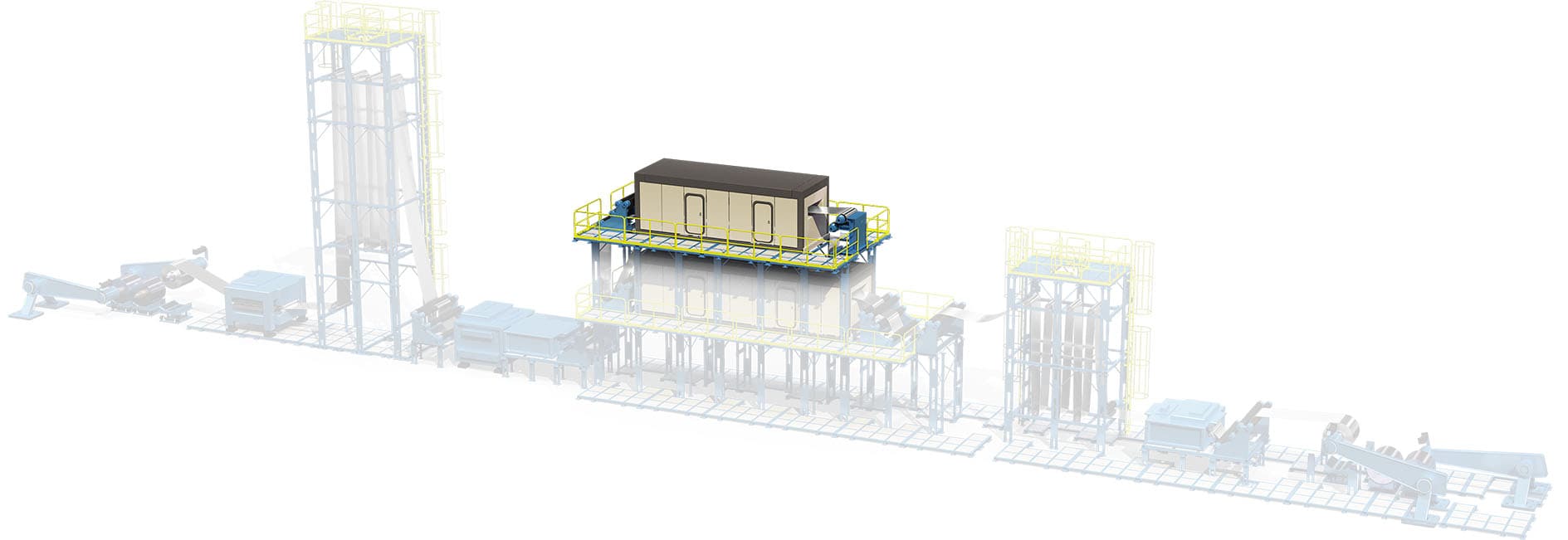

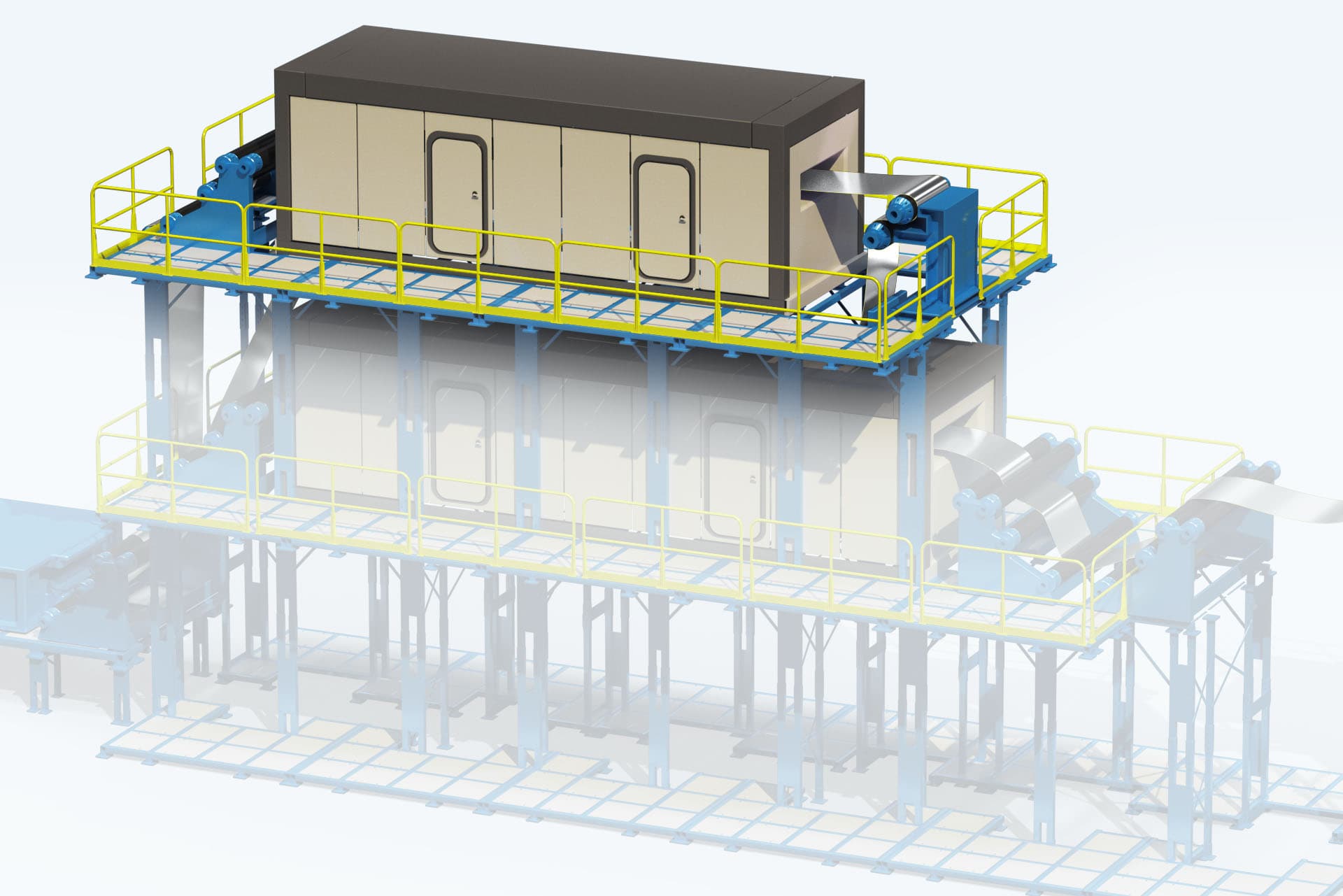

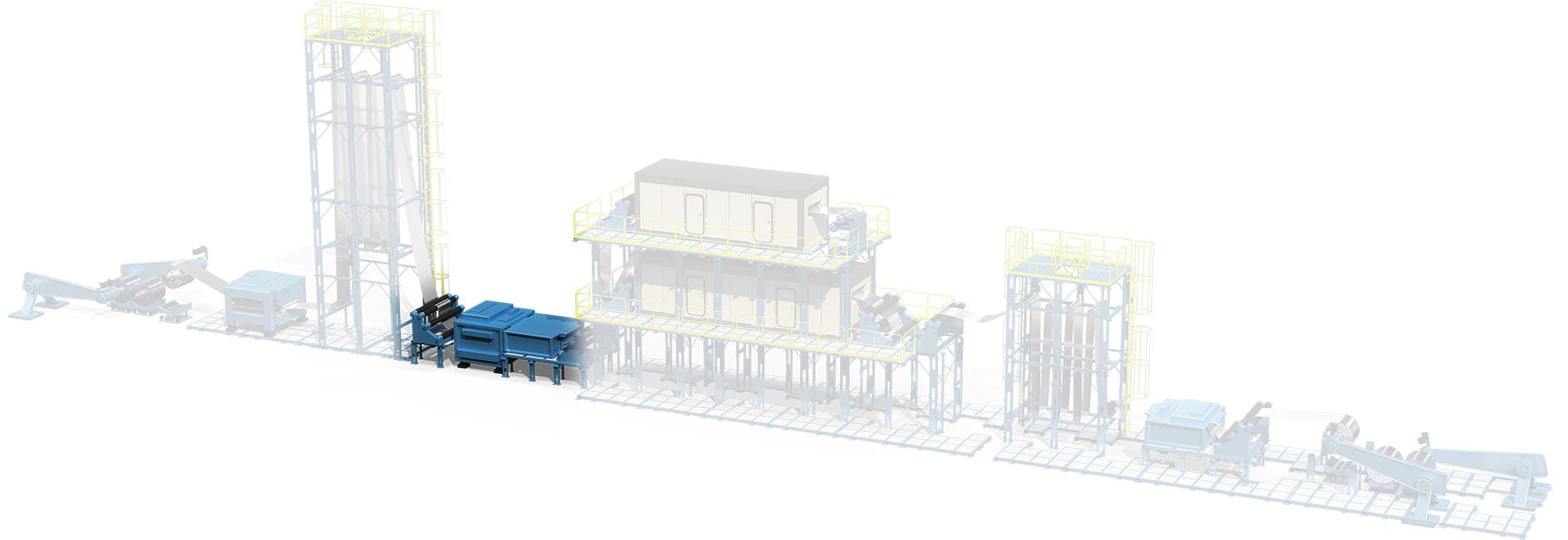

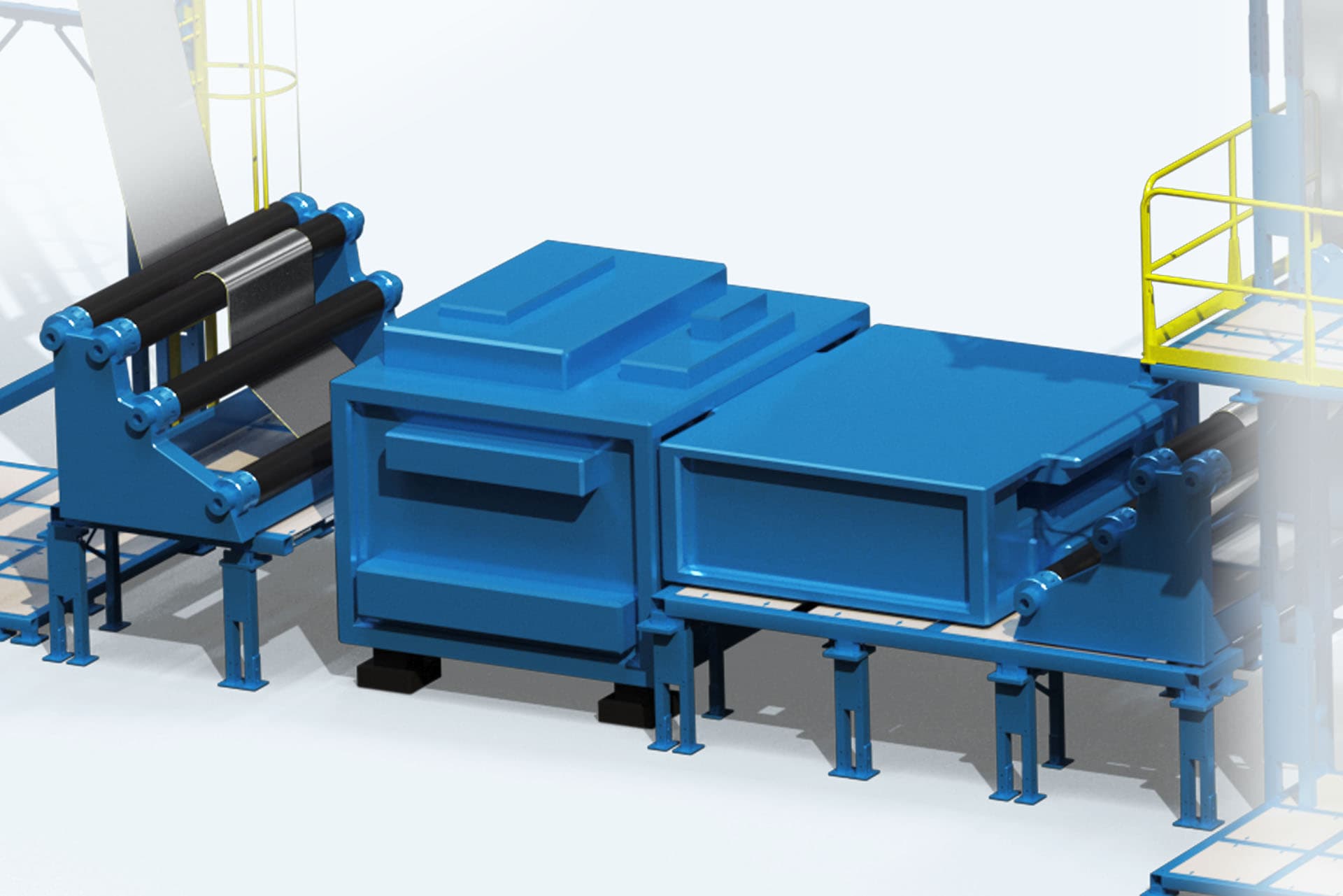

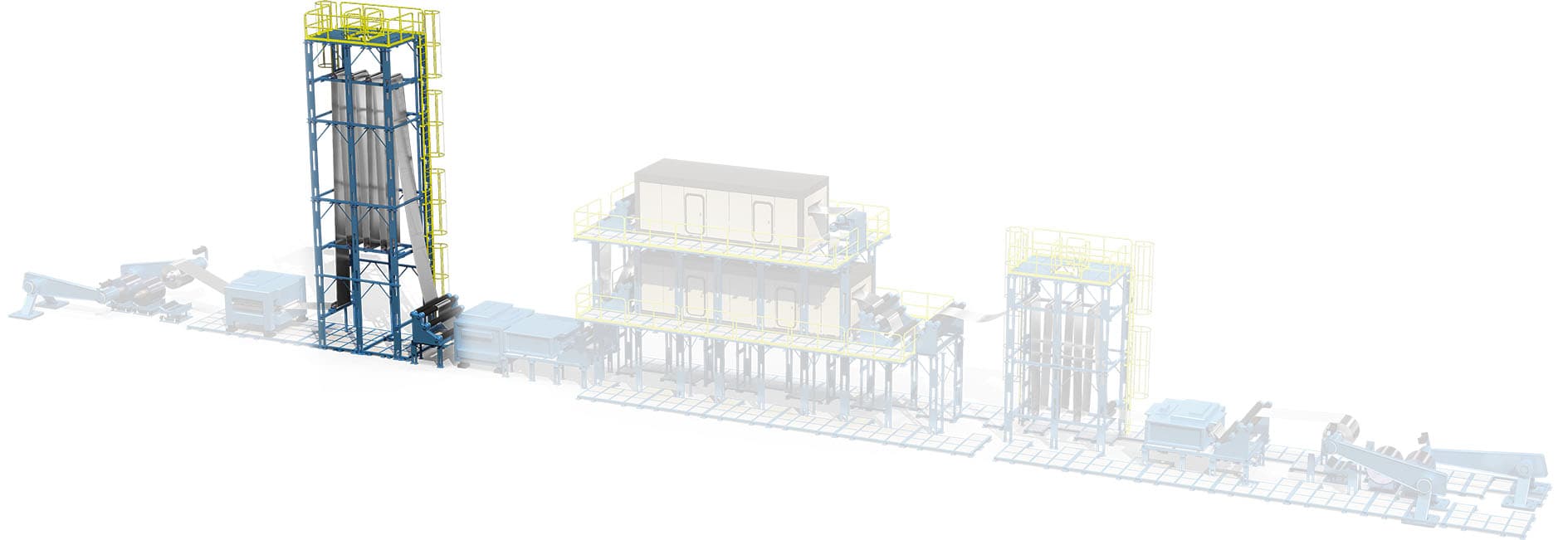

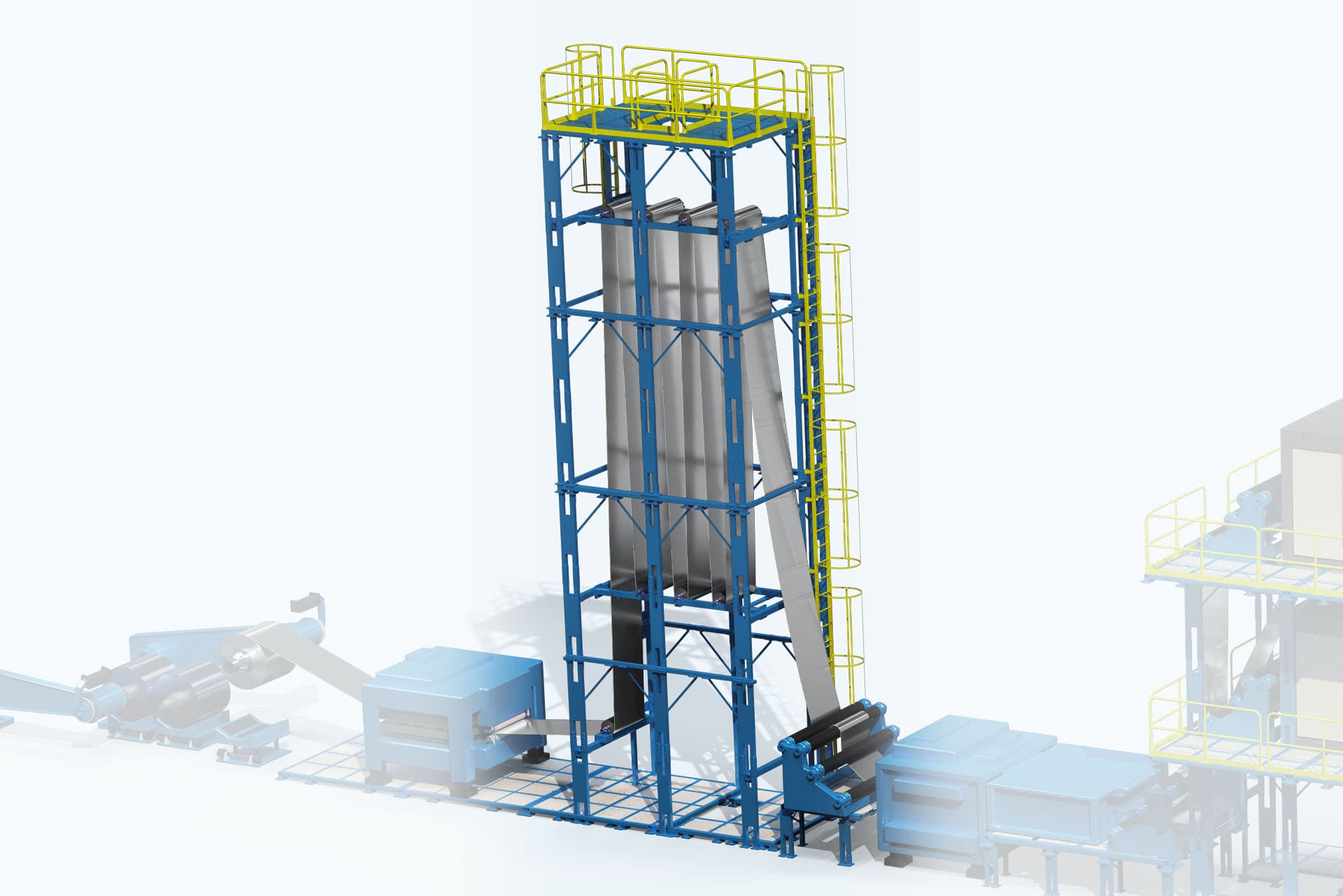

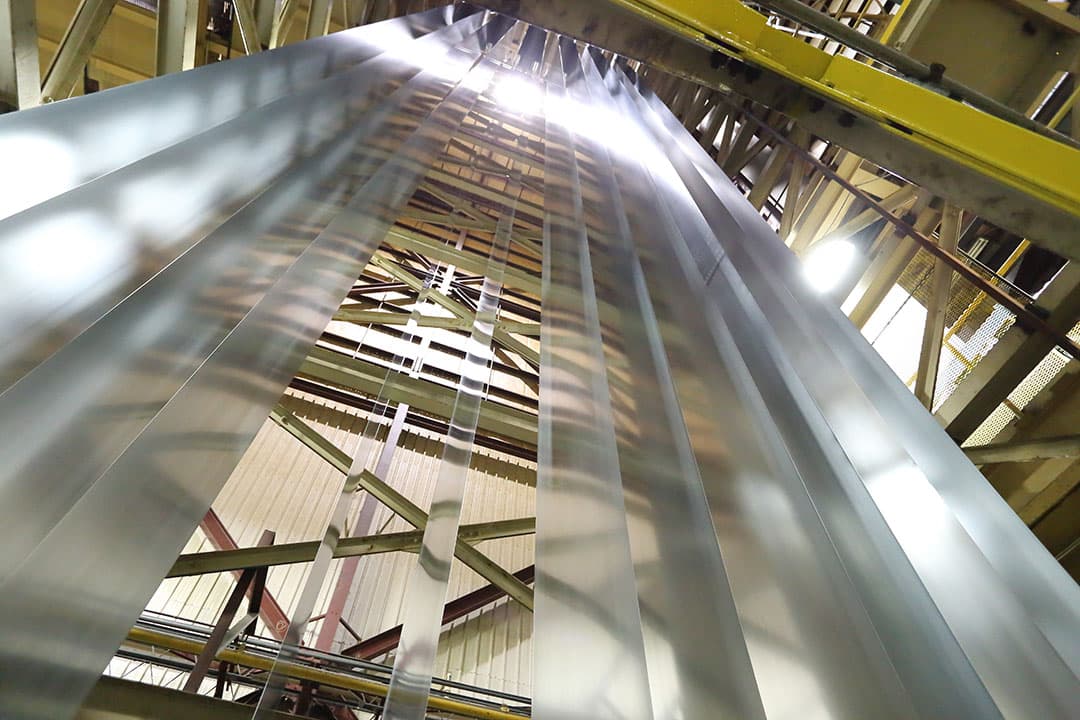

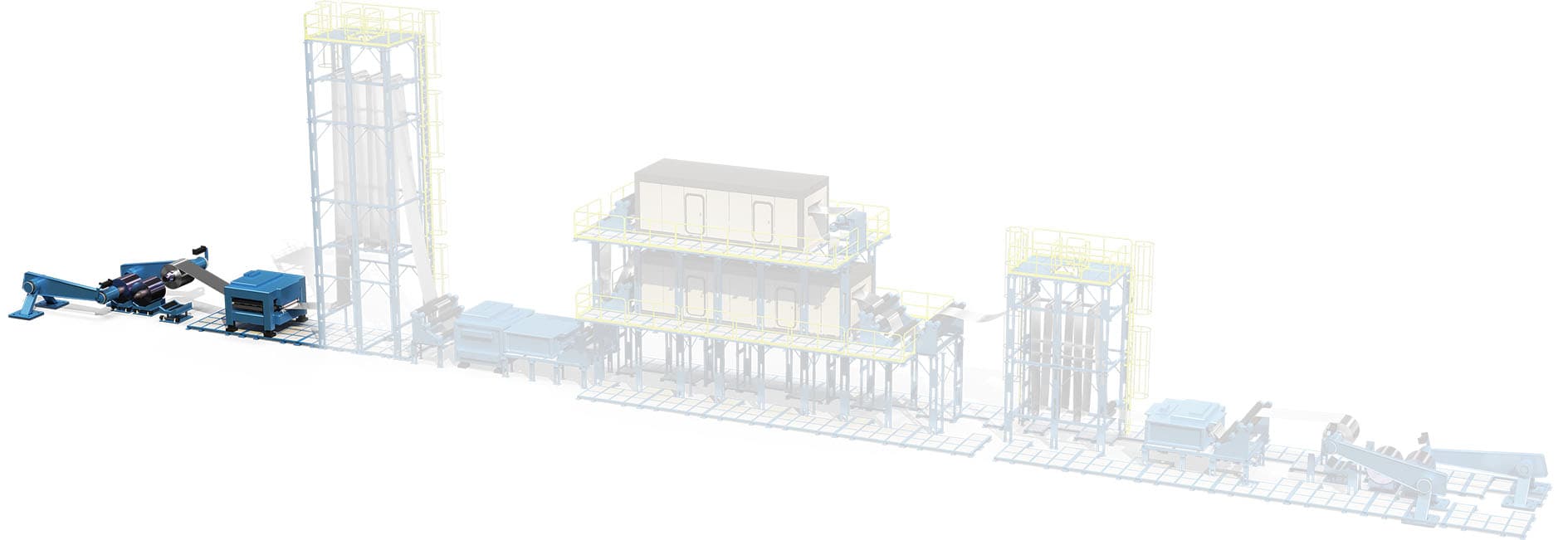

Spin galvanizing is a hot-dip process which utilizes a centrifuge anchored to a galvanizing kettle (or a spinner located above it) for immersing small to medium-scale components in molten zinc. A tightly bonded alloy coating forms on the steel, providing long-term, durable protection from the devastating effects of corrosion, while the centrifuge or spinner removes excess molten zinc to ensure coating uniformity, quality fits, and precise functionality.

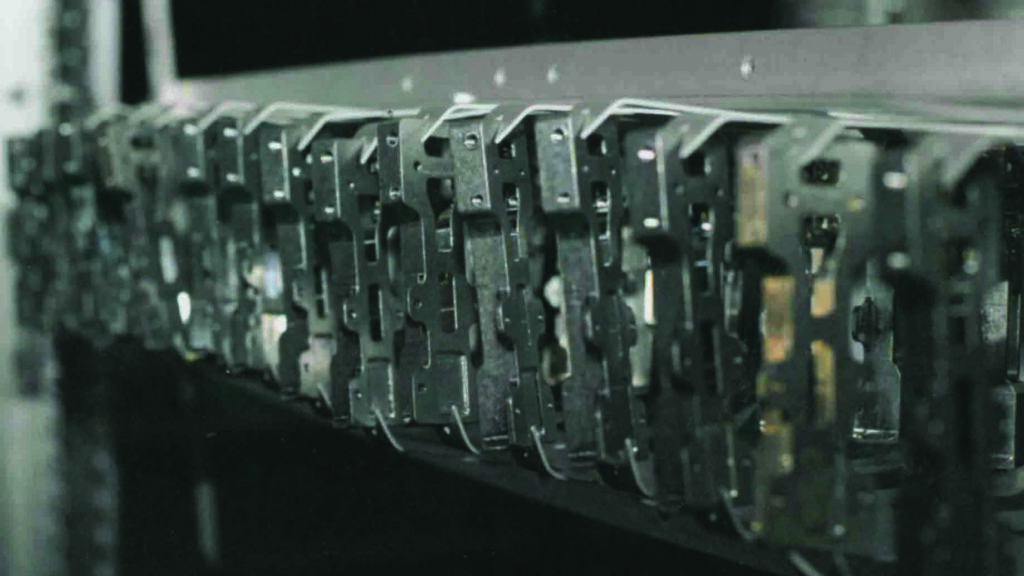

The spin process, combined with AZZ’s automated conveyor lines, are used for a wide range of small to medium sized components including all thread rods, nut blanks, guardrail bolts, anchor bolts, washers, turnbuckles, and wheels.

Here are just a few reasons to protect your small components with AZZ’s Spin Process:

1 – 100% Complete and Consistent Coverage

Our high quality spin process guarantees even coating for secure connections and lasting fits, while ensuring the visibility

of required identification and specification information engraved or stamped in the steel.

2 – Coating Thickness

Depending upon diameter, parts will receive from 1.7 to 3.4 (43 to 86 microns) mils of the impervious zinc coating. Zinc-plated components have a thin zinc coating, up to only 1 mil (25 microns).

3 – Bond Strength

Resulting bond strength nears 3600 psi (24.82 MPa). The coating is extremely difficult to damage. Painted and zinc plated coatings have a typical bond strength of only a few hundred PSI and are easily scratched and removed.

4 – Hardness

Spun parts have zinc-iron alloy layers, formed during the galvanizing process, that are harder than the base steel itself. These abrasion resistant layers make the galvanized coating difficult to damage during tightening.

5 – Paintable

Prepared according to ASTM D 6386 (Practice for Preparation of Zinc [Hot-Dip] Galvanized Coated Iron and Steel Product and Hardware Surfaces for Painting), hot-dip coatings are successfully painted, providing long-lasting under film corrosion protection.

Interested in learning more about AZZ’s rapidly expanding spin galvanizing capabilities? Contact us today!