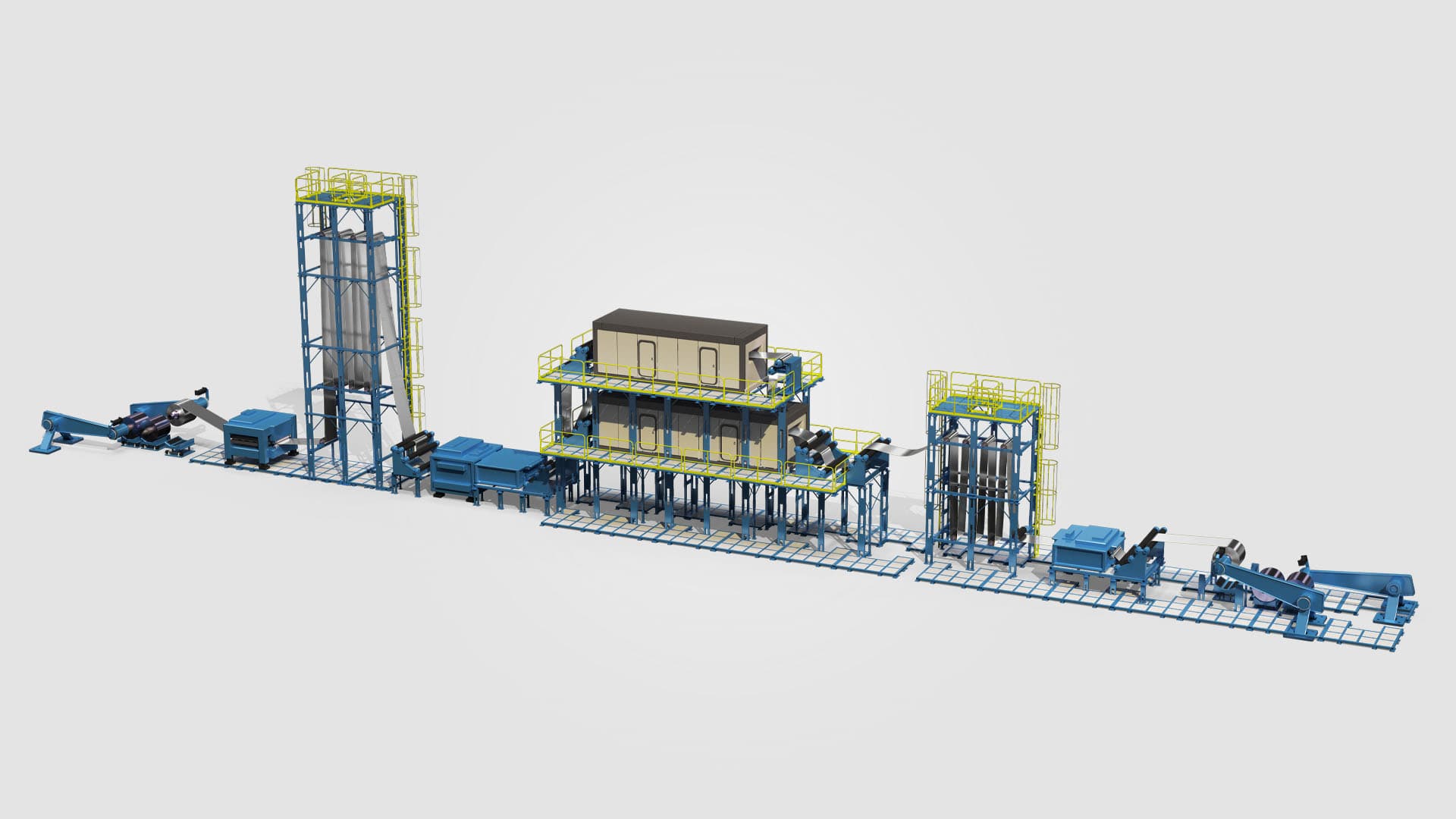

Shape Correction

Exceptional coil quality, ensuring superior final products

Shape correction is vital to rectifying shape and flatness issues in metal coils before further processing. This process involves straightening, leveling, or adjusting the coil to meet precise dimensional tolerances. Shape correction optimizes efficiency, producing superior metal products with improved dimensional stability and appearance.

Contact Us

Follow Precoat MEtals

CoilZone Login

Visit CoilZone

Your secure, interactive, supply chain management system.

Locations

Capabilities by Precoat Metals location

Learn About our Advantages

Coil Coating Process

Explore the continuous, automation of our coil coating process ensuring uniform, high-quality metal coated finishes before fabrication

Why Choose Coil Coating

Streamline processes, reduce costs, enhance product quality, and explore innovative coatings

Cleaning & Pretreating

Ensures the quality, durability, and performance of coated products