Capabilities

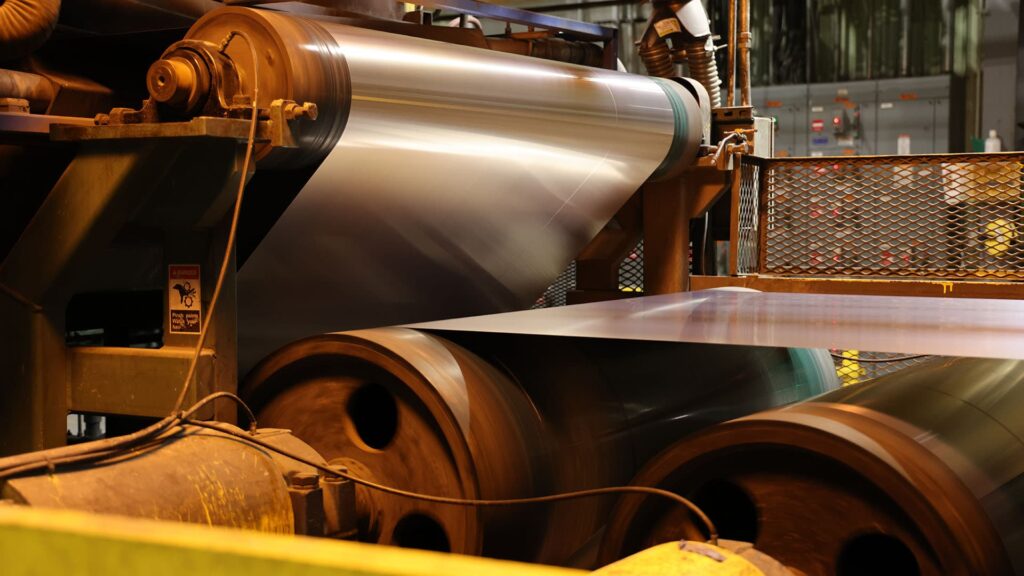

Coil coating is widely recognized as the most efficient and cost-effective method for pre-painting steel and aluminum substrates. This continuous and automated process involves coating metal before its fabrication. Doing so ensures a high-quality finish and offers numerous advantages, including enhanced productivity, consistent coating thickness, improved durability, and reduced environmental impact.

Transforming ordinary metal into extraordinary solutions

AZZ Precoat Metals is North America’s leading independent coil coating supplier, with over 3 million tons of available coating capacity across 15 coating lines spanning 13 locations. Our distinction as an industry leader isn’t solely anchored in our vast volume; it’s deeply rooted in the service to our valued customers. We can dedicate lines and technical support to specific coating applications and market sectors, such as appliance, construction, transportation, container, and consumer products.

We are well suited to accommodate multiple metal sourcing options and a wide range of metal substrates such as carbon steels, coated steels, aluminum, and stainless steel. We offer additional in-house processing such as slitting, cut-to-length, embossing, film lamination, printing, shape correction, cleaning & pretreating, and product innovation.

Cleaning & Pretreating

Ensures the quality, durability, and performance of coated products

Shape Correction

Improves stability and appearance, meeting precise dimensional tolerances

Precoat Metals Locations