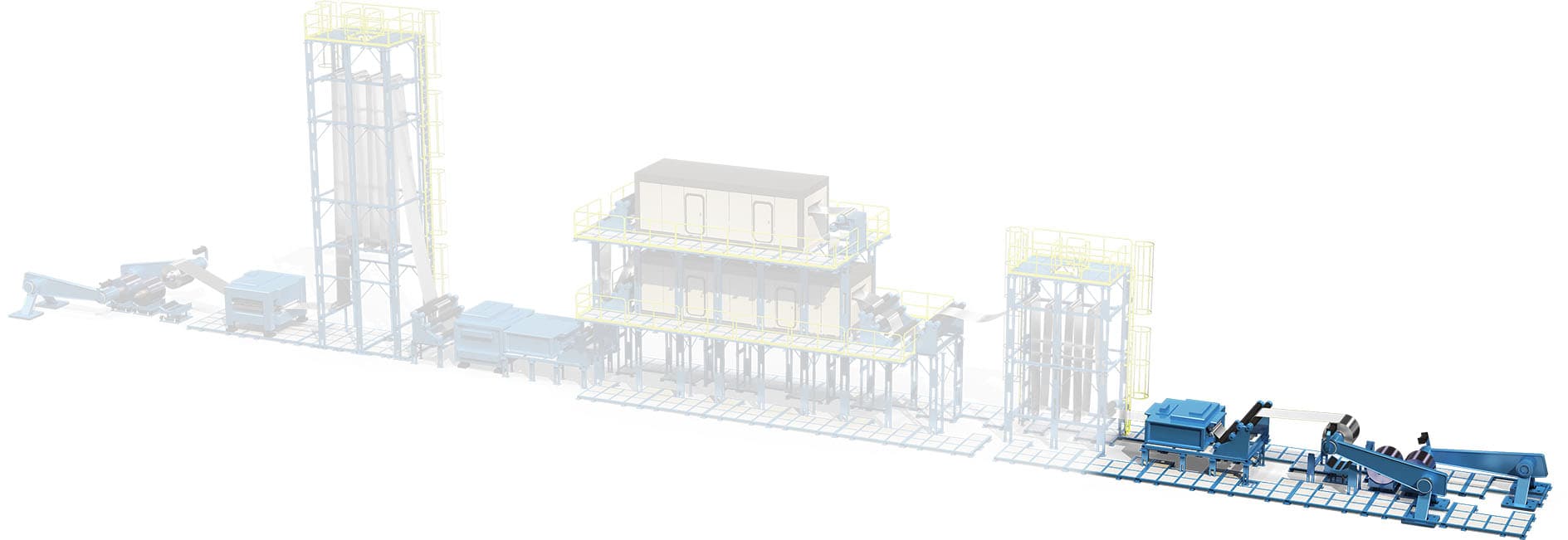

Galvanizing

North America’s largest hot-dip galvanizer of fabricated steel

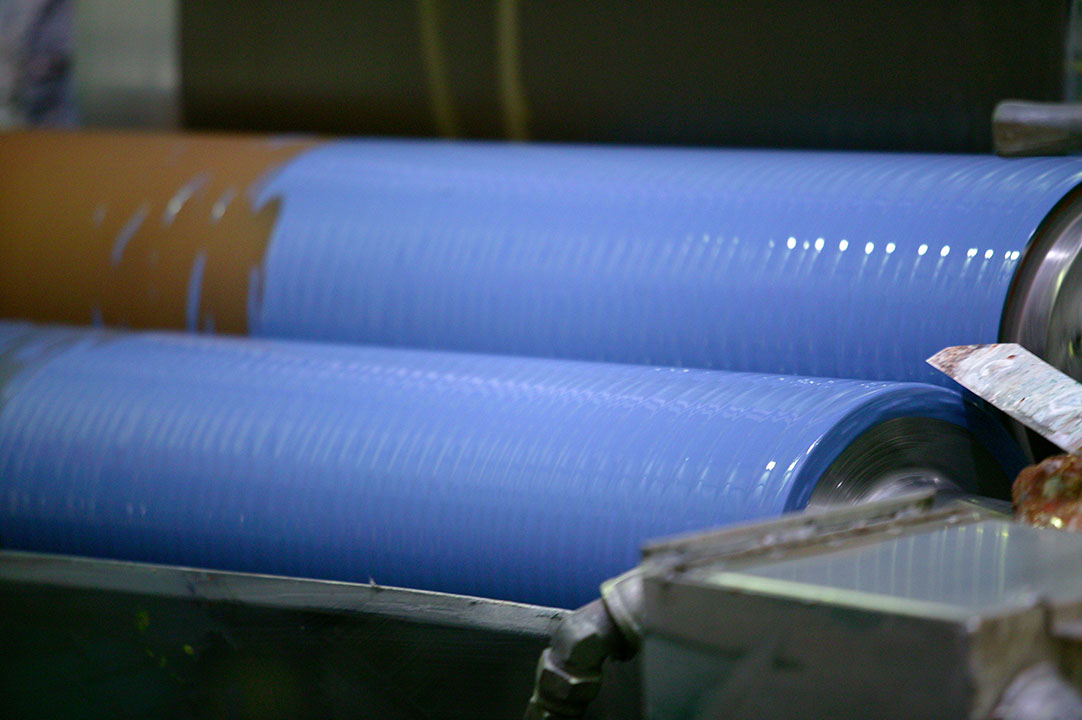

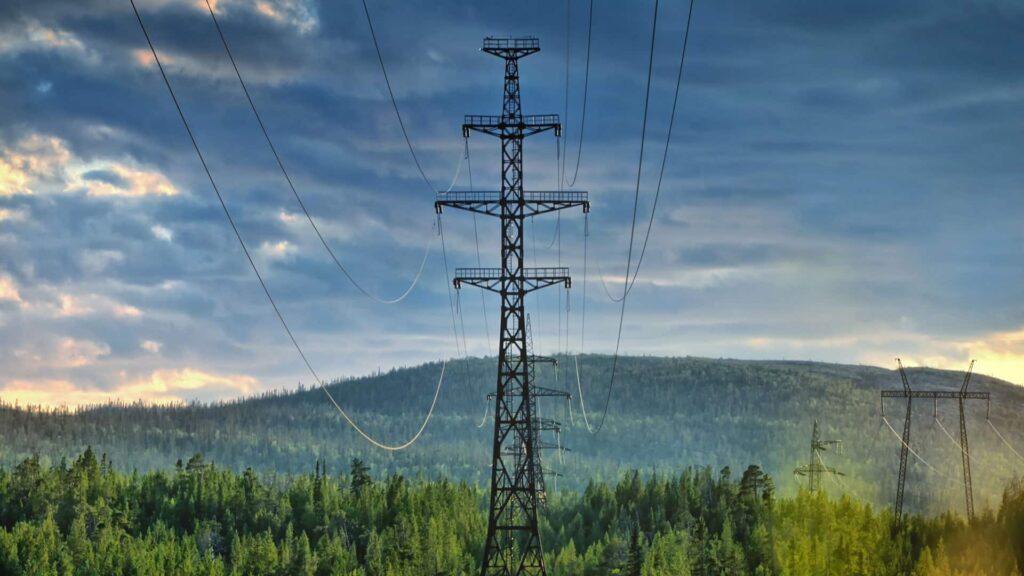

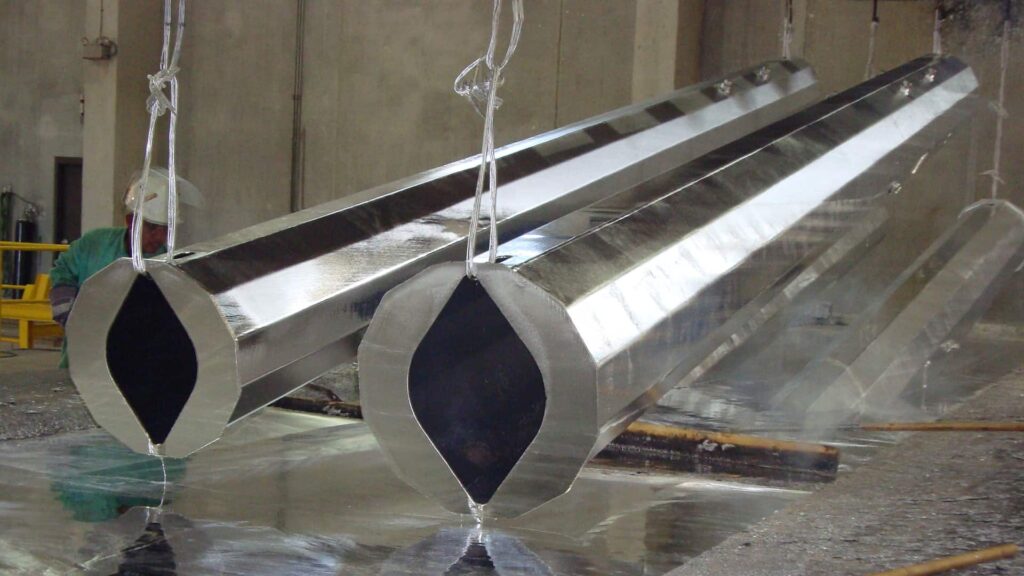

Hot-dip galvanizing has been utilized for over 250 years to protect steel and iron from the destruction of corrosion. The process, which has evolved over the years, entails dipping fabricated steel into a kettle of molten zinc. The iron in the steel reacts with the zinc to form a tightly bonded alloy coating which protects the steel from corrosion. Galvanized steel has a significantly lower life cycle cost than other materials such as painted steel or epoxy coated surfaces, and requires no coating maintenance over its service life.

Trusted Experience and Expertise

A leading provider of hot-dip galvanizing, AZZ has over 45 galvanizing operations throughout the U.S. and Canada providing maximum accessibility and thereby reducing transportation costs for our valued customers. Our extensive experience and expertise extend to a broad range of applications including agriculture, bridge and highway, construction, electrical utilities, original equipment manufacturers, petrochemicals, recreation and transportation.

Explore Galvanizing

Accreditations

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

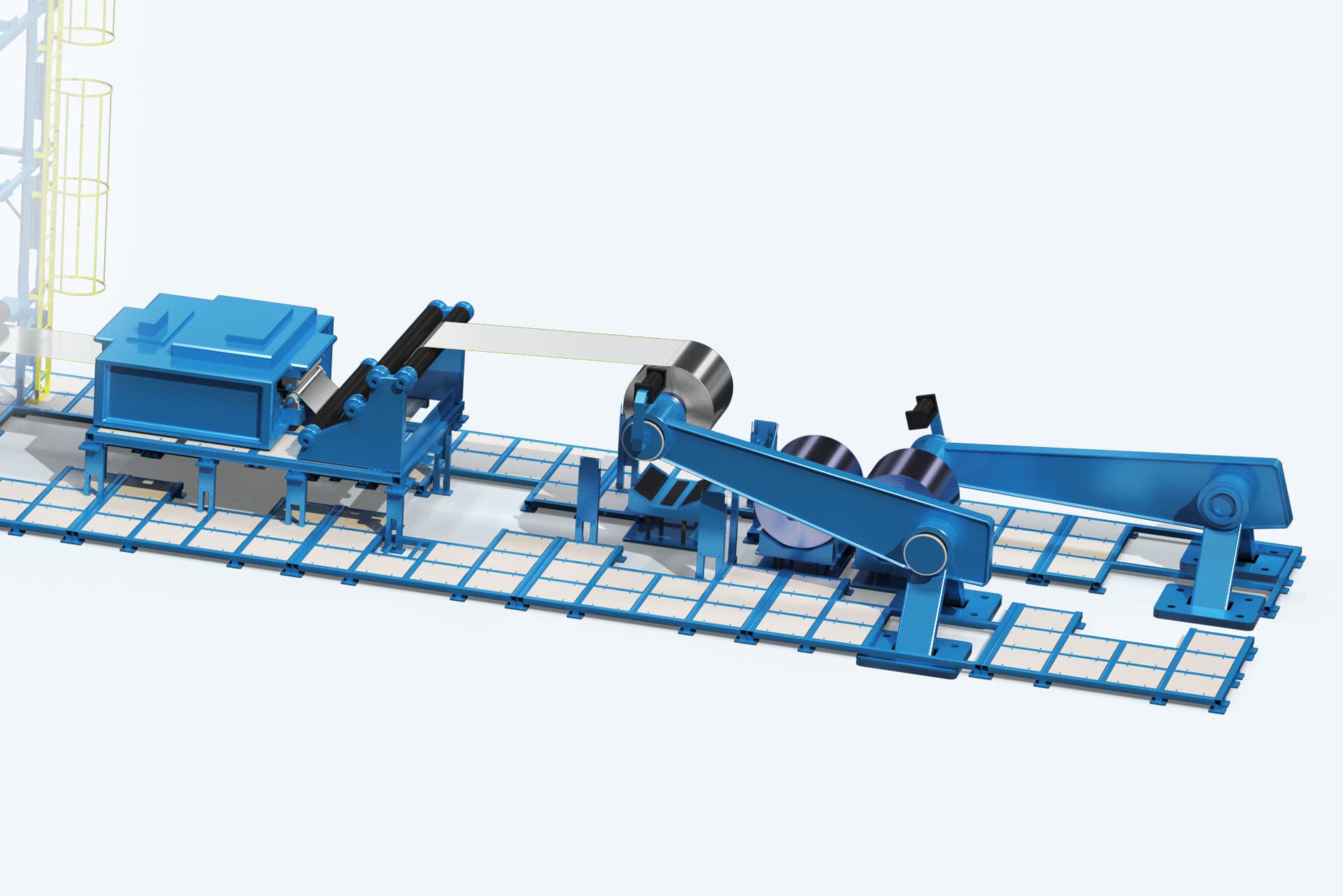

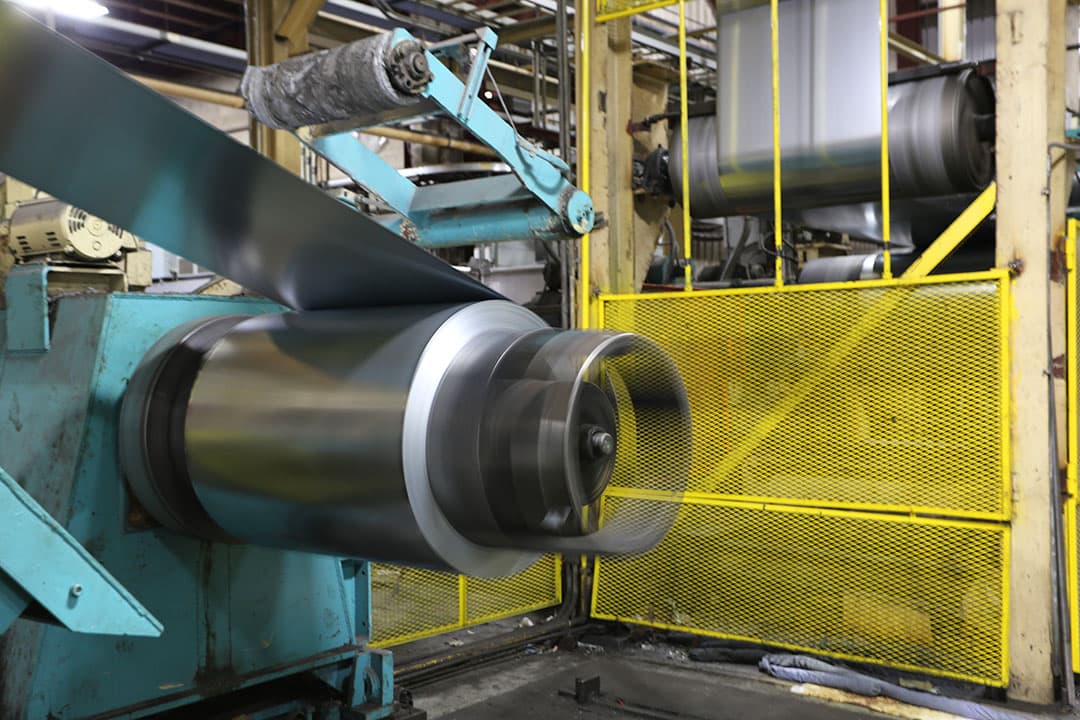

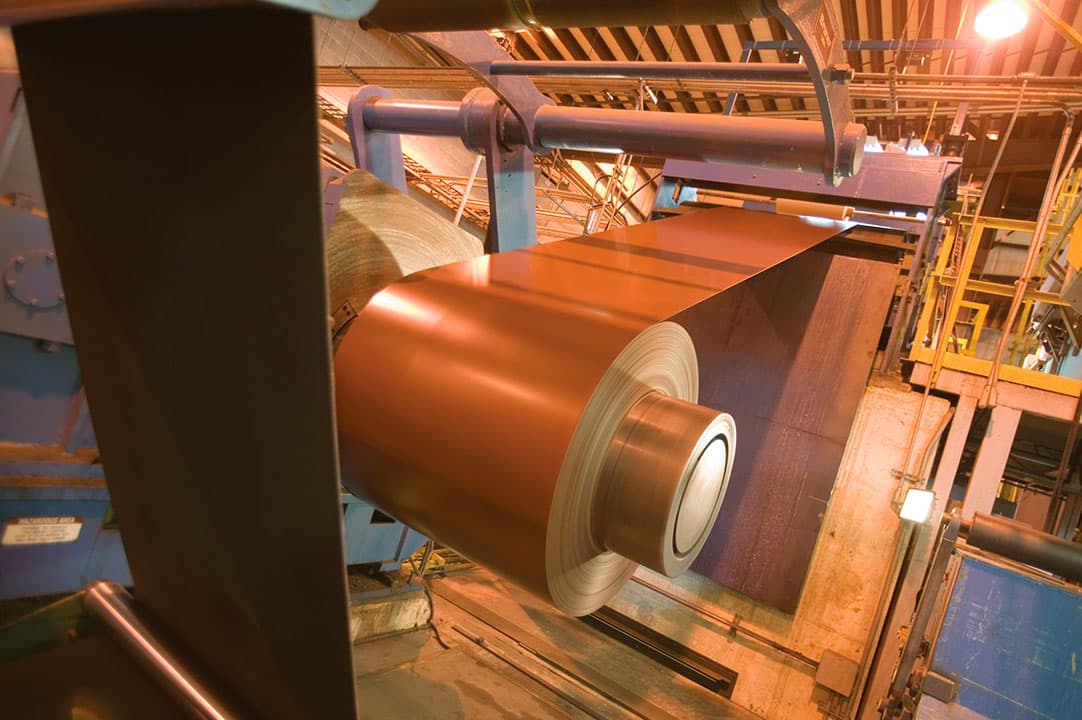

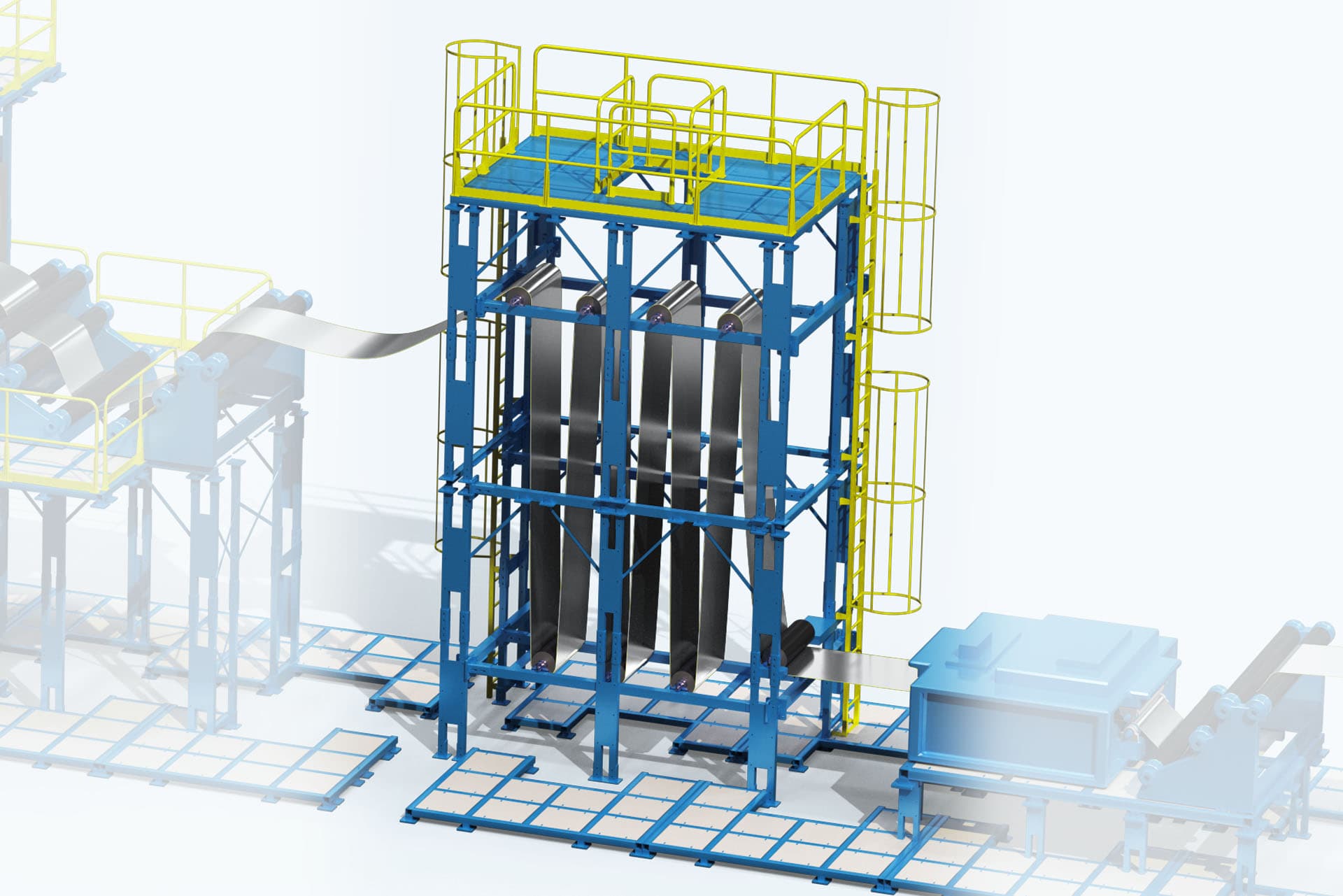

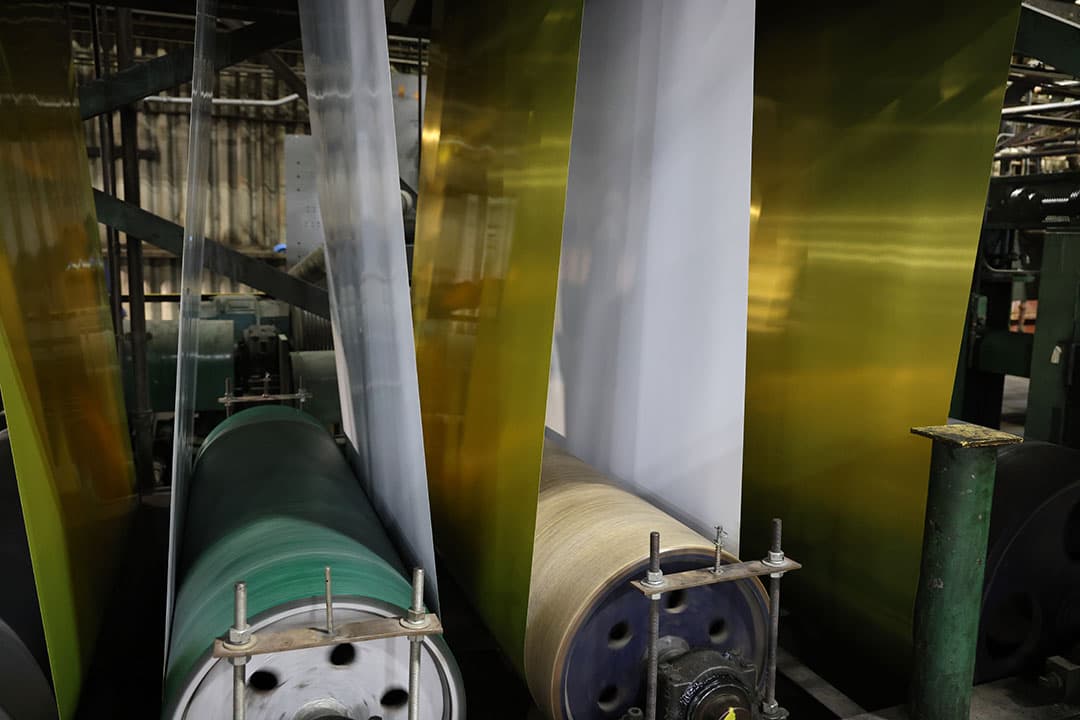

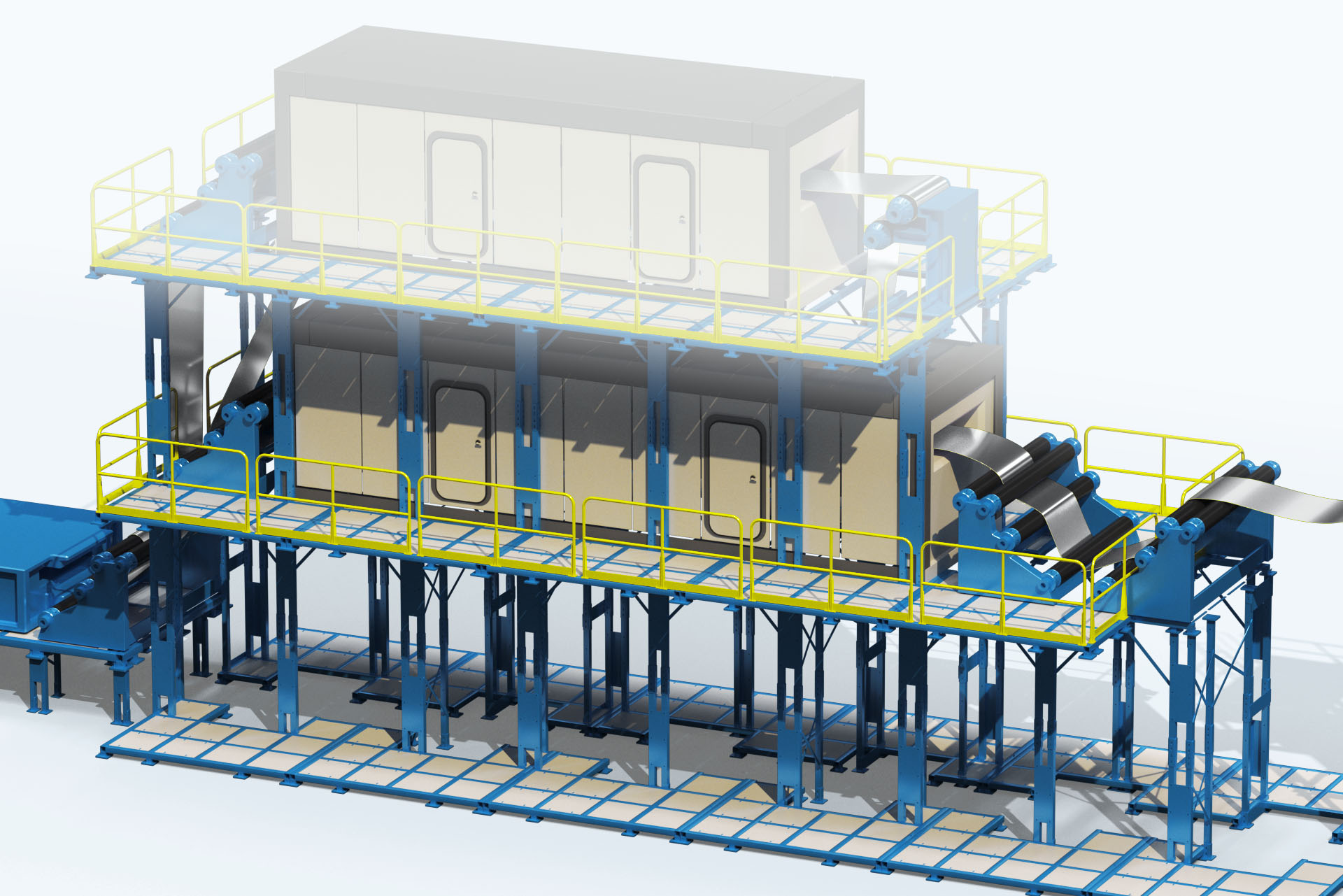

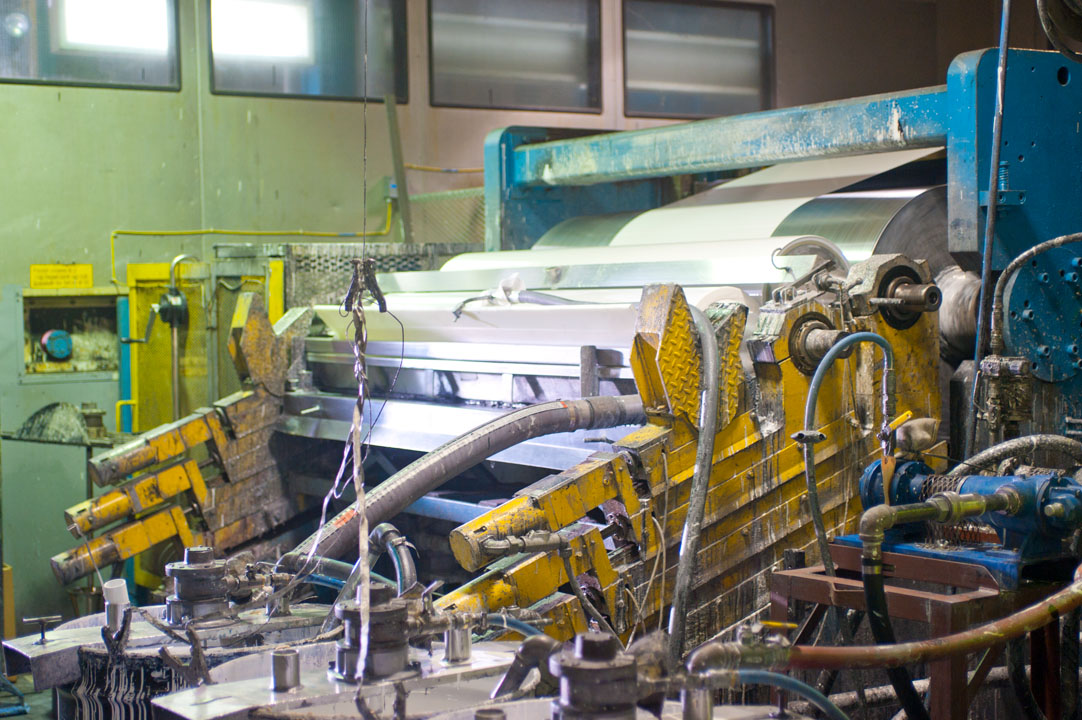

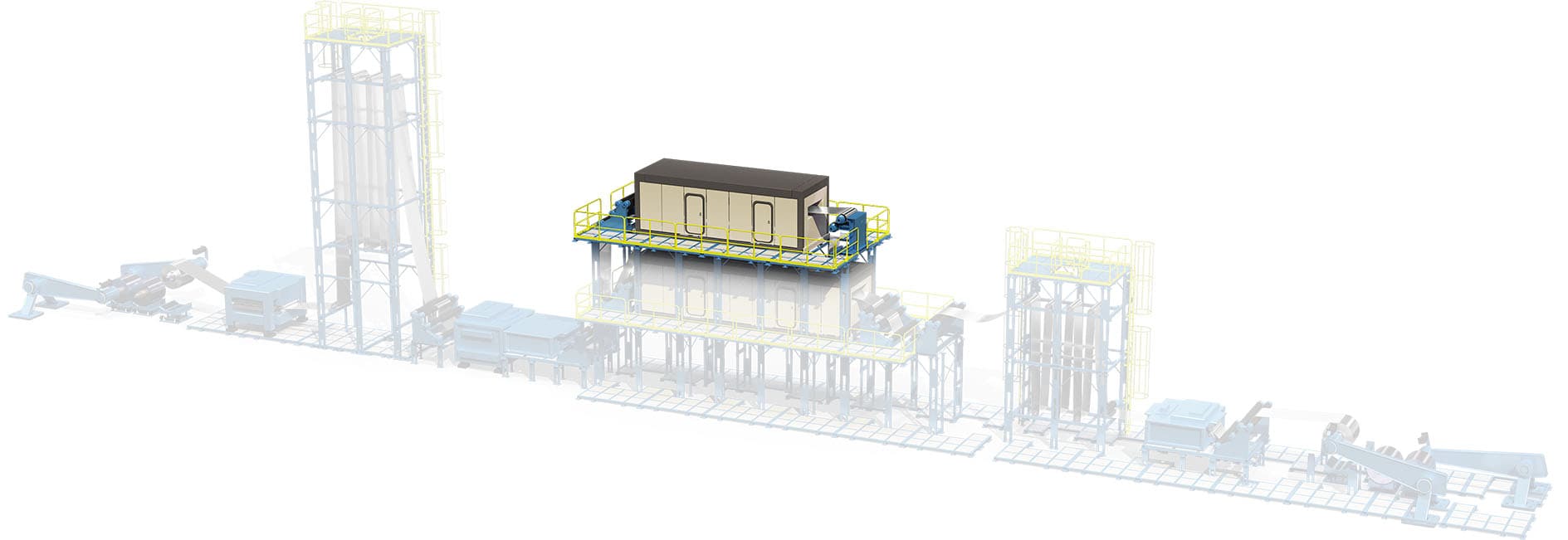

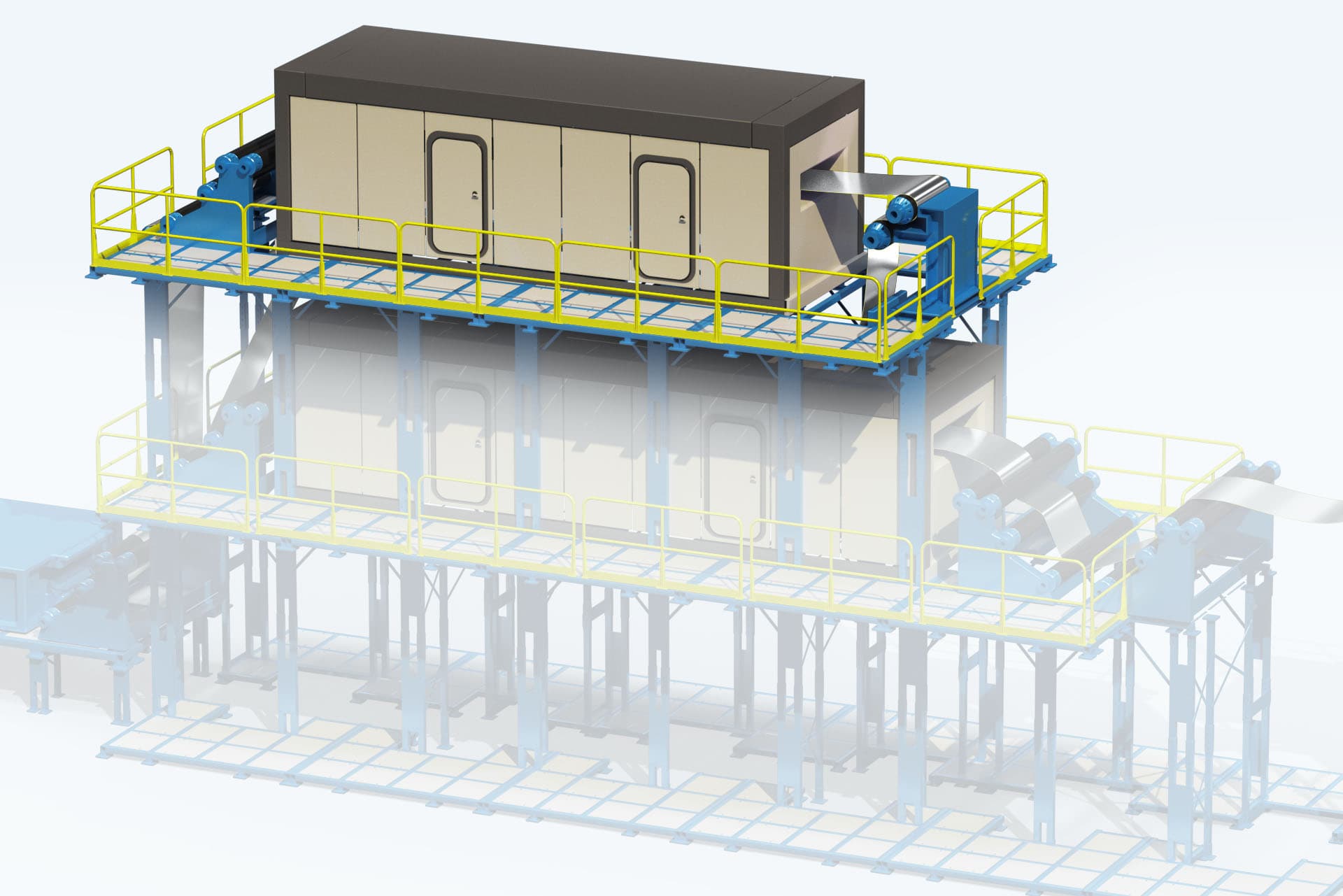

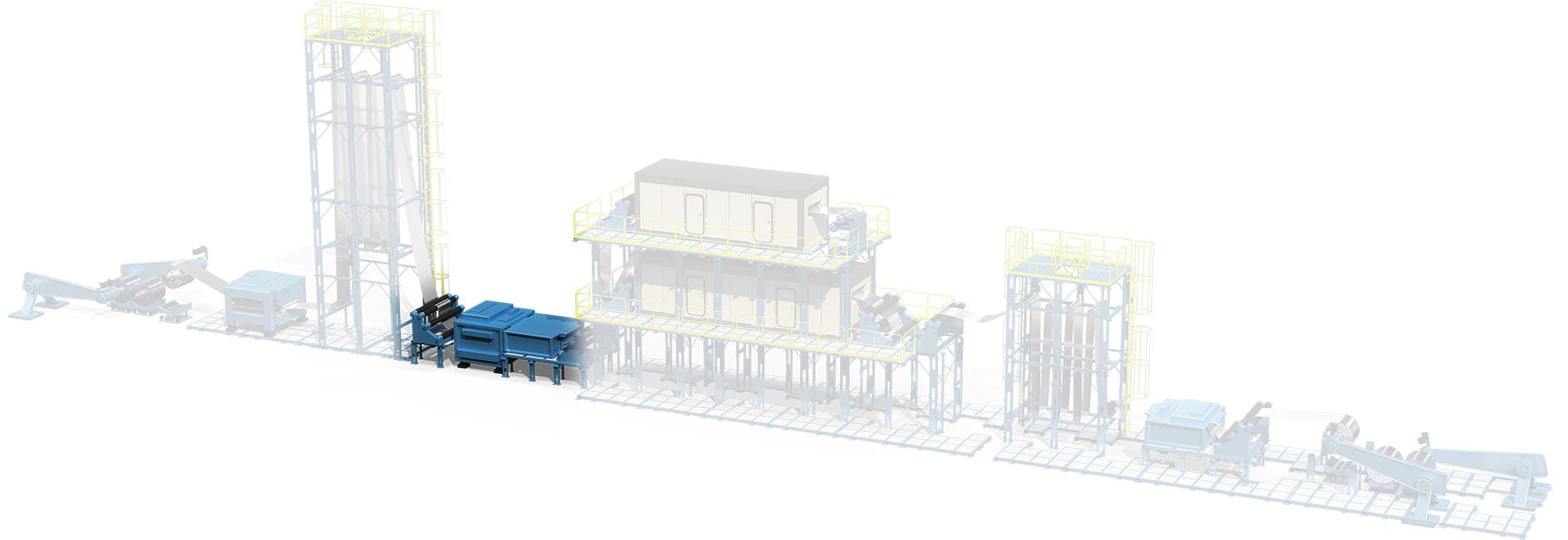

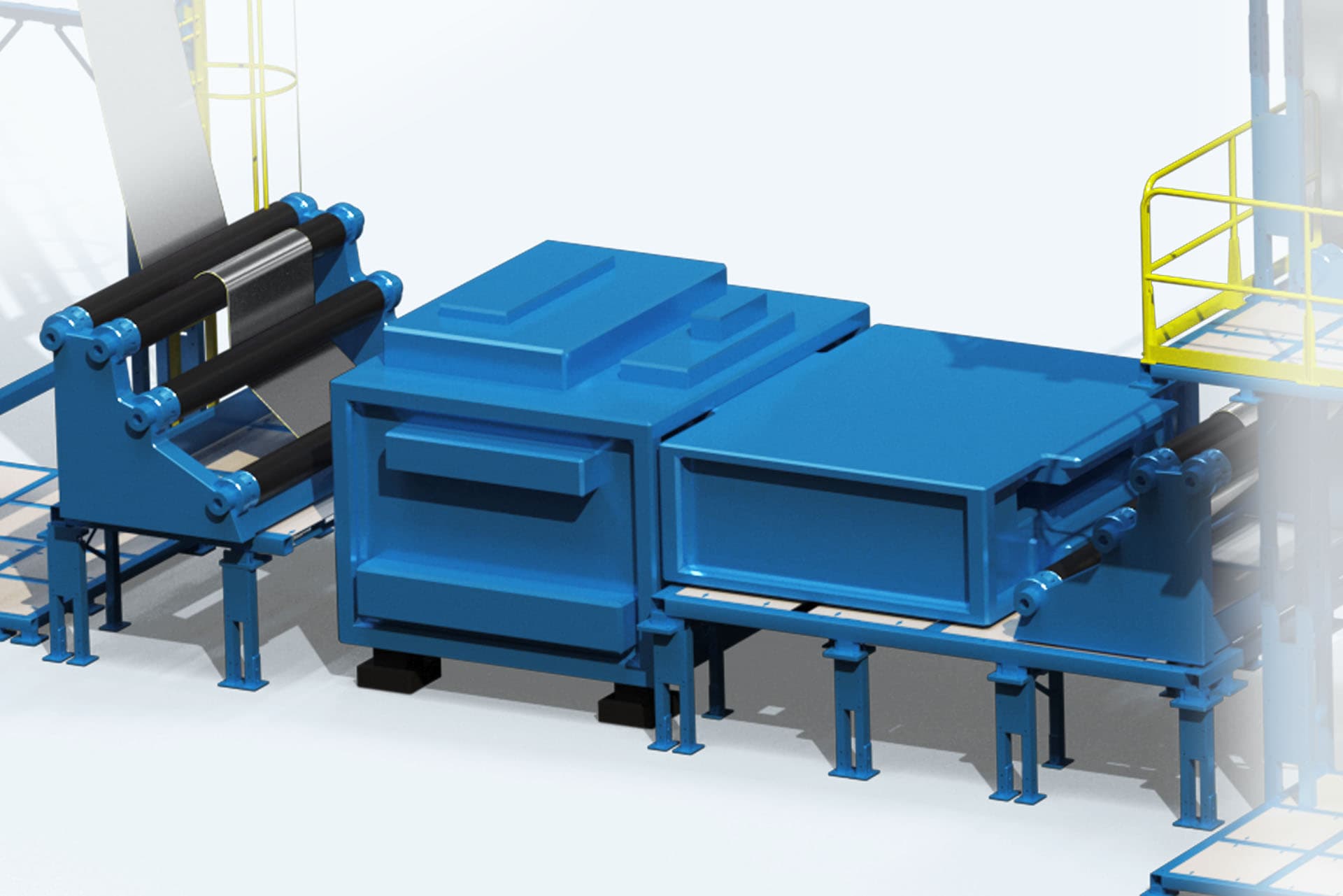

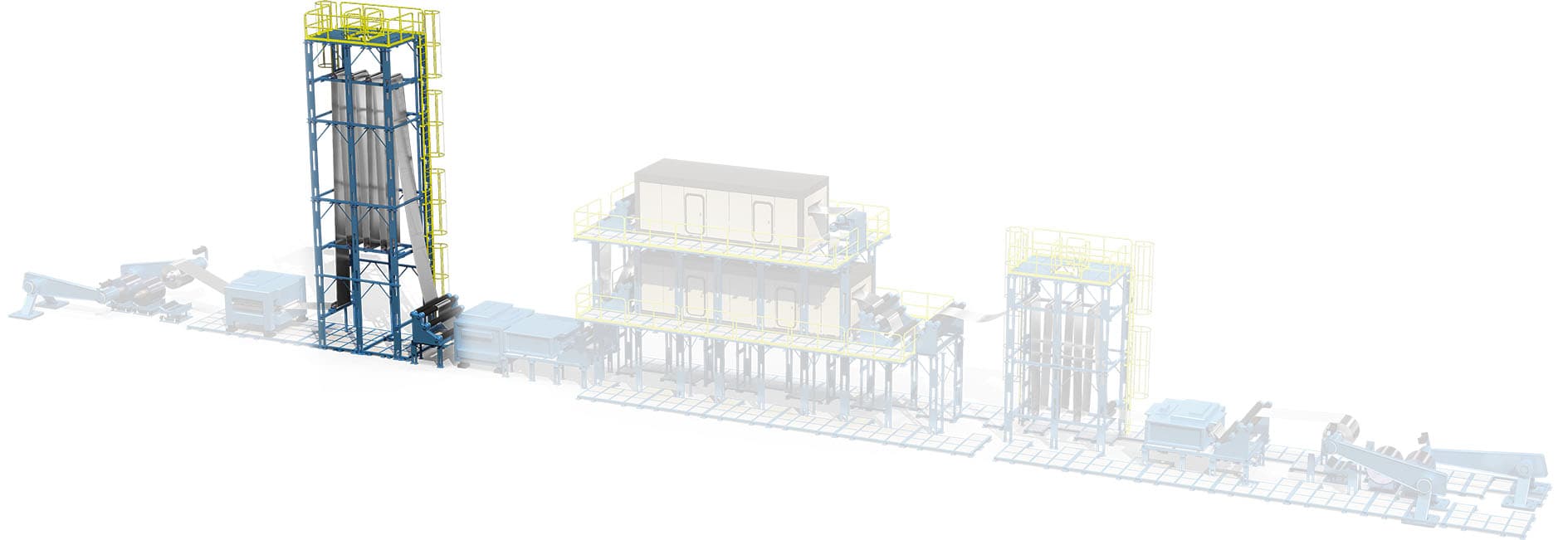

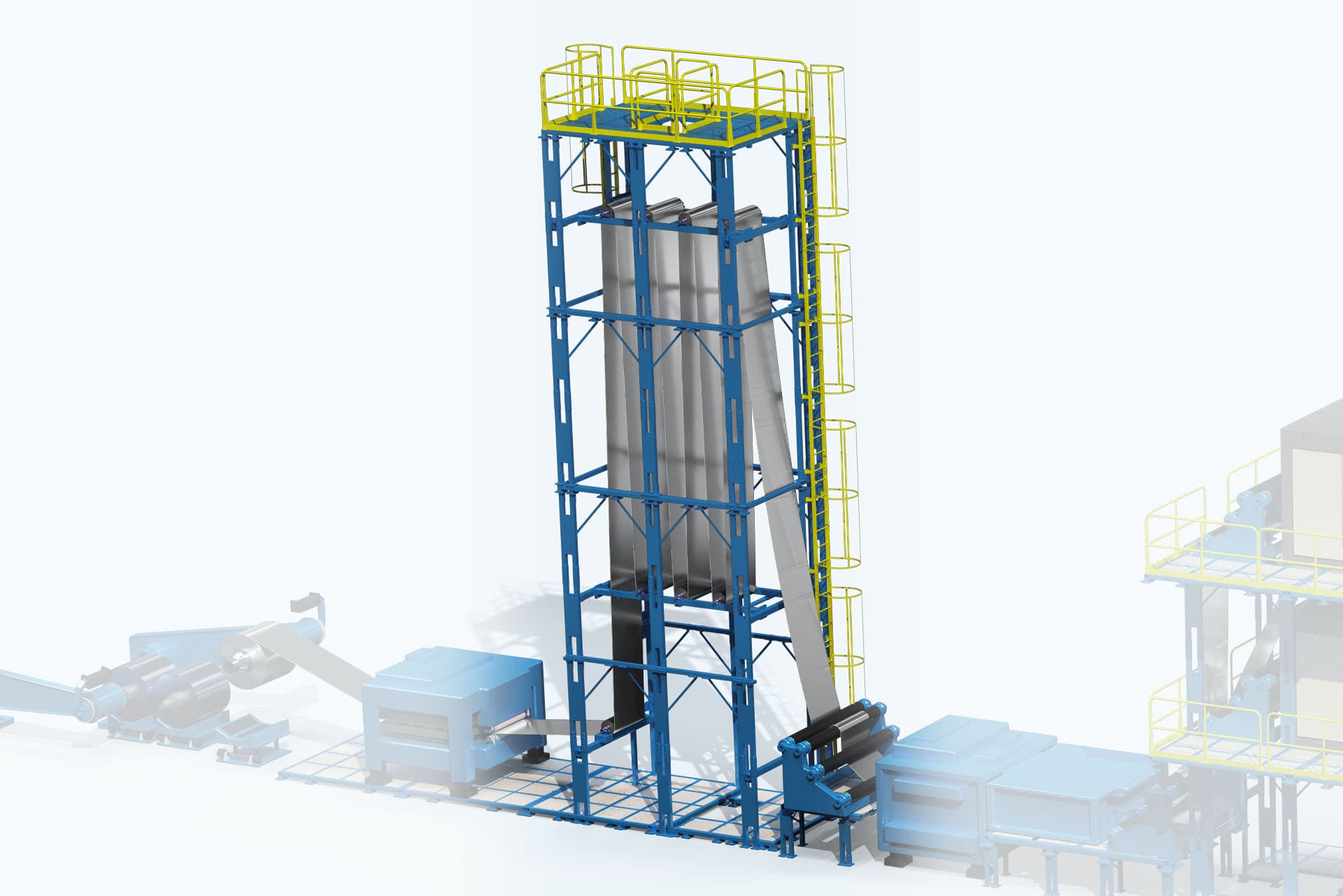

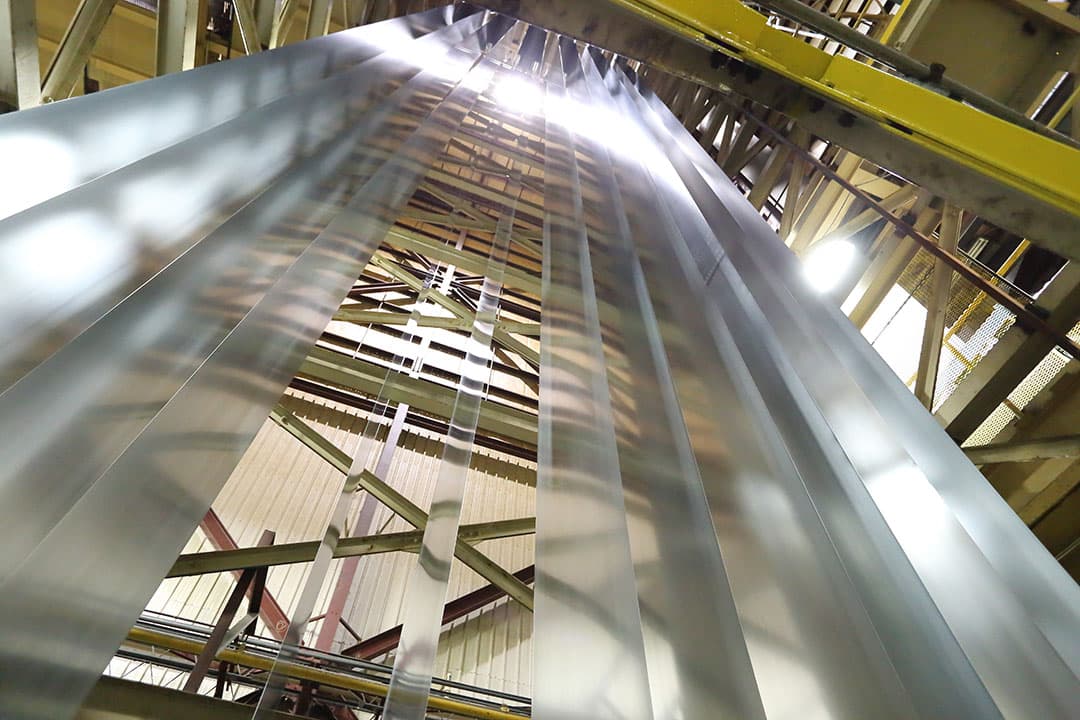

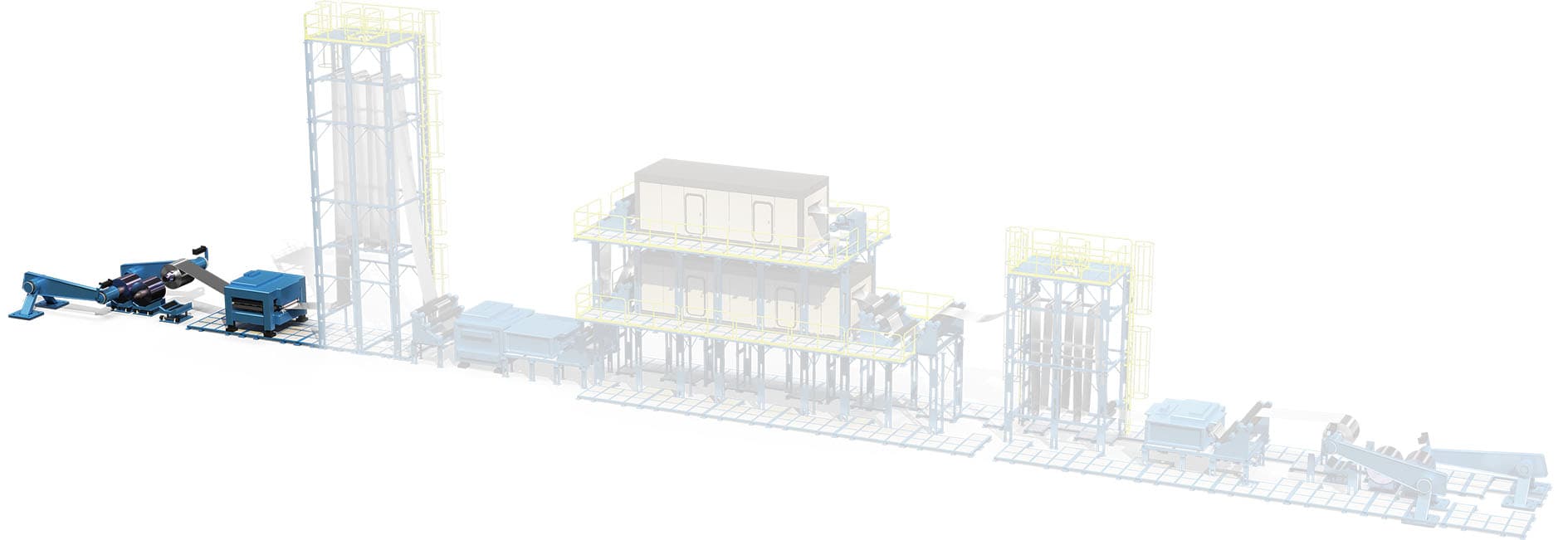

Hot-Dip Galvanizing Process

Hot-Dip Galvanizing Process

A tested and proven galvanizing process ideal for modern applications

Spin Galvanizing

Spin Galvanizing

Cost-effective corrosion protection for small to mid-sized steel components

Galvanizing Locations